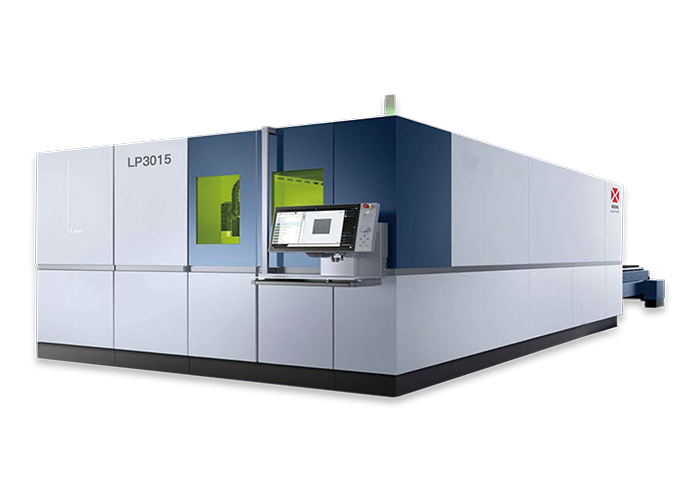

SafewellGroup Laser cutting Equipment

Laser cutting machine is an efficient and accurate processing equipment which uses high-energy laser beam to cut materials quickly. With the rapid development of the manufacturing industry, laser-cutting machine has been widely used in various fields. Our customer is a company producing secret cabinet products; the company encountered cutting problems in the production process, successfully solved the problem through the introduction of a laser cutting machine, and achieved significant economic benefits.

VOC:

The company mainly produces steel products, such as secret cabinets, steel furniture, etc. During the production process, they encountered the following problems:

Cutting accuracy requirement is high: the cutting of cold-rolled steel material needs very high accuracy, otherwise, it will directly affect the quality and aesthetics of products.

Cutting faster: The company needs to do a lot of cutting tasks in a short period of time to maintain productivity.

Cutting costs should be reasonable: the company wants to reduce cutting costs as much as possible while ensuring quality.

Advantages of laser cutting machine:

For the customer's cutting requirements, the laser cutting machine has the following advantages:

High accuracy: the cutting accuracy of the laser cutting machine can reach ± 0.1mm, which can meet the company's requirements for cutting accuracy.

Fast speed: the laser cutting machine's cutting speed is extremely high, can complete a large number of cutting tasks in a short time.

Good quality: the cutting surface of the laser cutting machine is smooth, with no burr, and can improve the quality and beauty of the products.

Implementation plans:

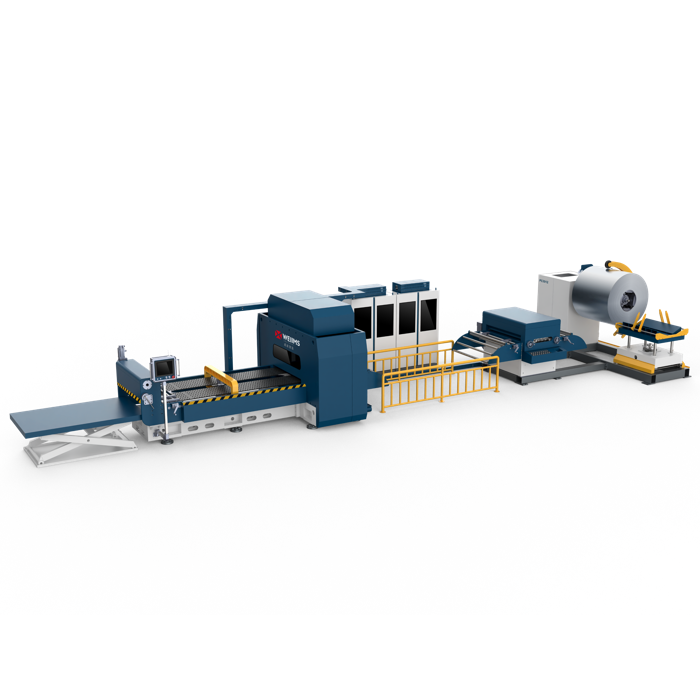

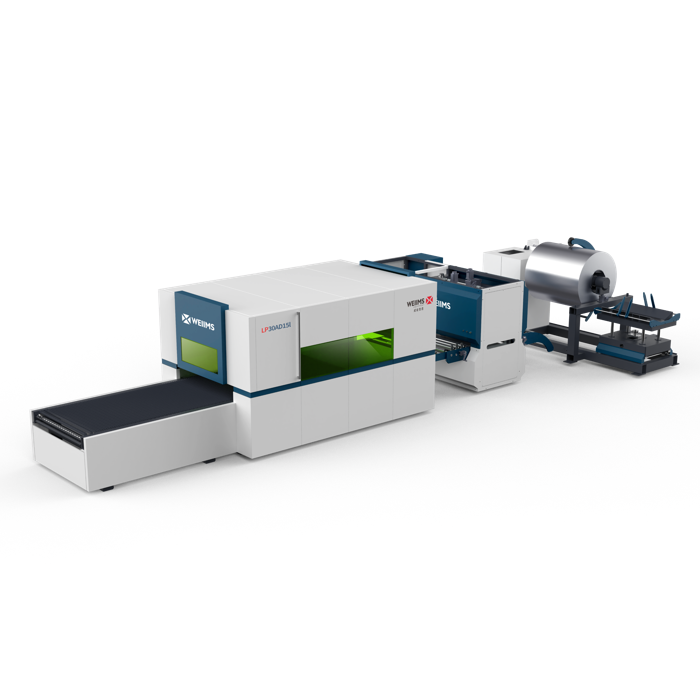

To meet the needs of our customers, we provide the company with the following laser-cutting machine implementation plan:

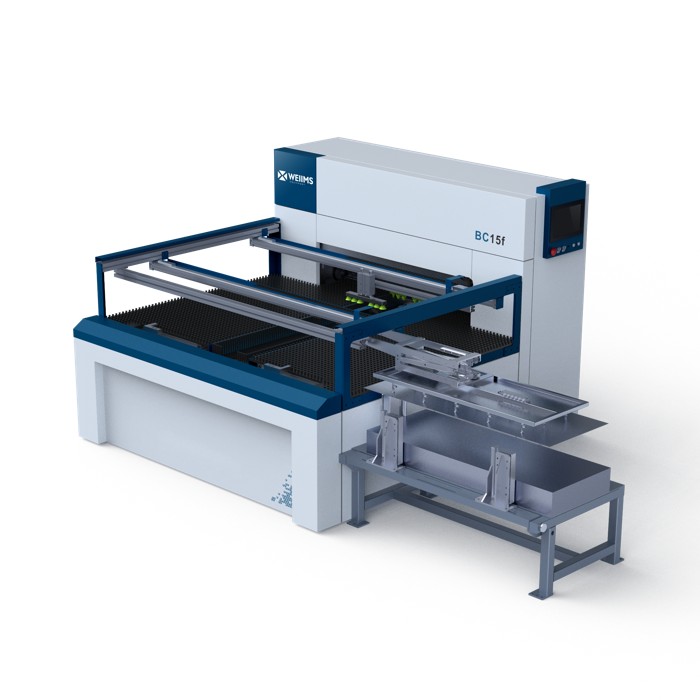

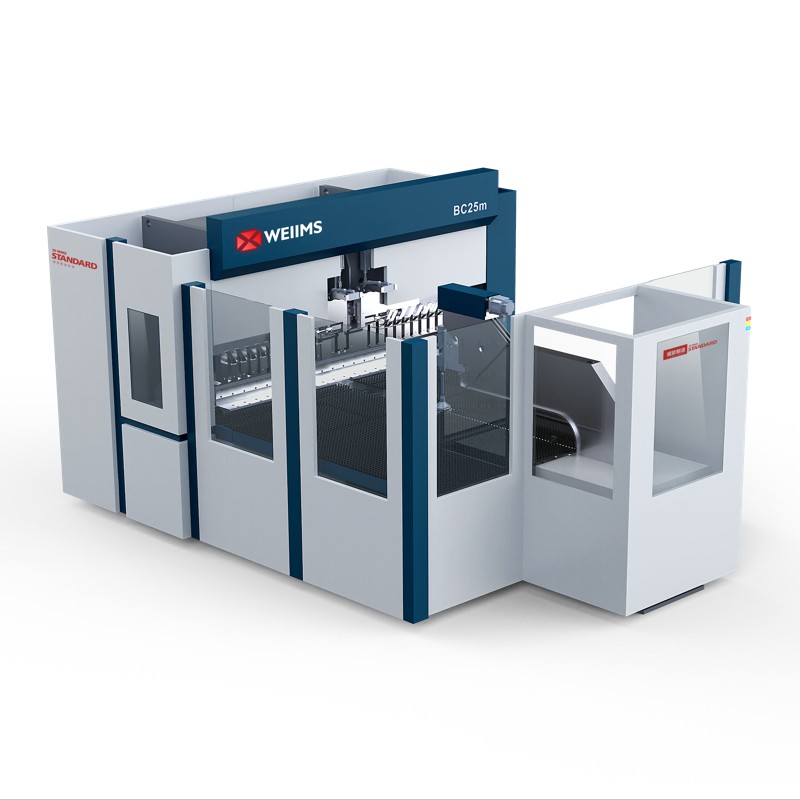

Scene selection: For the cutting of cold-rolled steel materials, we chose a special laser cutting machine with high precision and high speed.

Operation method: We send professional technicians to the company for on-site operation

training to ensure that the operators can master the operation method of the laser cutting machine.

Technical details: During the implementation process, we pay attention to the details to ensure the operation stability and accuracy of the laser cutting machine.

Effect assessment:

After a period of use, the customer has evaluated the effect of the laser cutter:

Cutting quality: the cutting quality of laser cutting machines has been recognized by customers, and the quality and beauty of products have been significantly improved.

Production efficiency: By introducing laser cutters, the company's production efficiency has been greatly improved, thus reducing production costs.

Cost-effectiveness: Compared with the traditional mechanical cutting method, the laser cutting machine has more advantages in cost, saving a lot of production costs for customers.

In this customer case, we successfully solved the cutting problems encountered in the production process by introducing a laser cutting machine. The advantages of high precision, fast speed, and high quality of the laser cutting machine have been fully reflected. The customer is satisfied with the implementation effect and believes that the application of laser cutting machines is of great significance to improve product quality, production efficiency and reduce cost.Through this case, we realize that the application prospect of laser cutter in cold production of rolling steel products is promising. With the continuous development of science and technology, laser technology will continue to innovate and improve, and the future laser cutting machine is expected to be widely used in more fields. We will continue to focus on our customers' needs and provide professional solutions to create more value for our customers.