Excellent edge-bending center

Enterprise general situation

Luoyang Hefeng Company is an enterprise focusing on office furniture manufacturing, after 20 years of development, has become a certain influence in the industry enterprises. The company has an experienced research and development team and production technology team, to provide a full range of services from design to production.

In recent years, with the increasing expansion of the market and increasing competition, the company's requirements for production efficiency and product quality are also increasing. In order to meet the market demand and improve the production efficiency, the company decided to introduce the advanced edge bending center equipment.

“bottleneck identification”

In the past, the company used the traditional manual bending method, low production efficiency, and the product quality is difficult to guarantee. Due to the different skill levels of the workers, the bending Angle and size often have certain errors, which require multiple adjustments and corrections. This not only increases production costs, but also affects delivery times and customer satisfaction.

In addition, workers are prone to fatigue during long-time and high-intensity bending work, which may also lead to industrial accidents. Therefore, the company urgently needs to introduce an efficient and accurate bending equipment to improve production efficiency and product quality.

"a ready-made panacea"

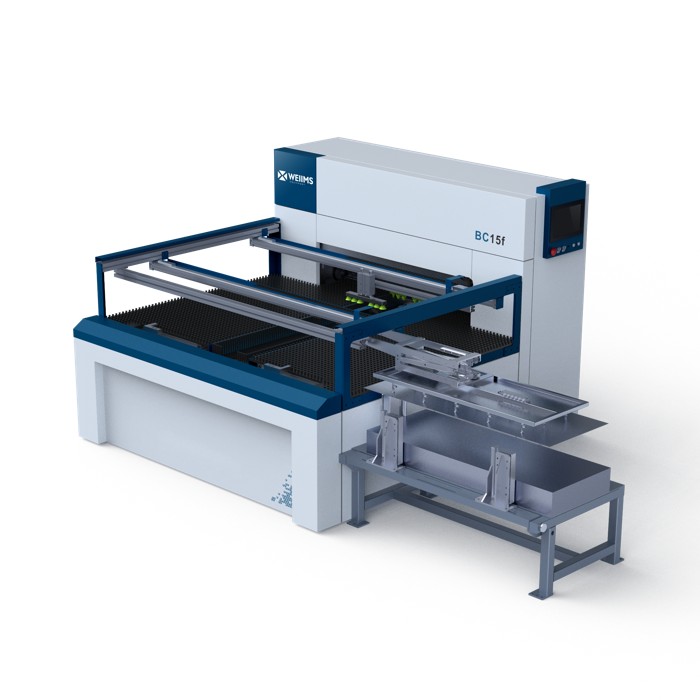

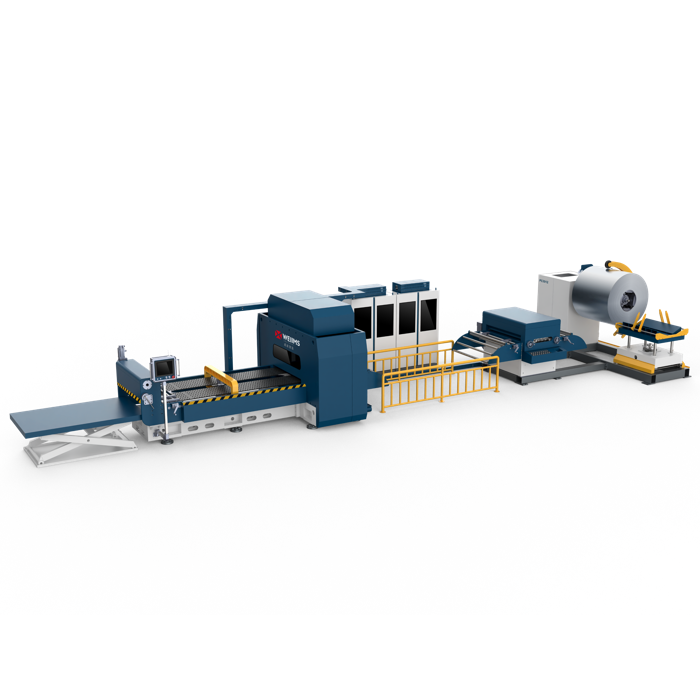

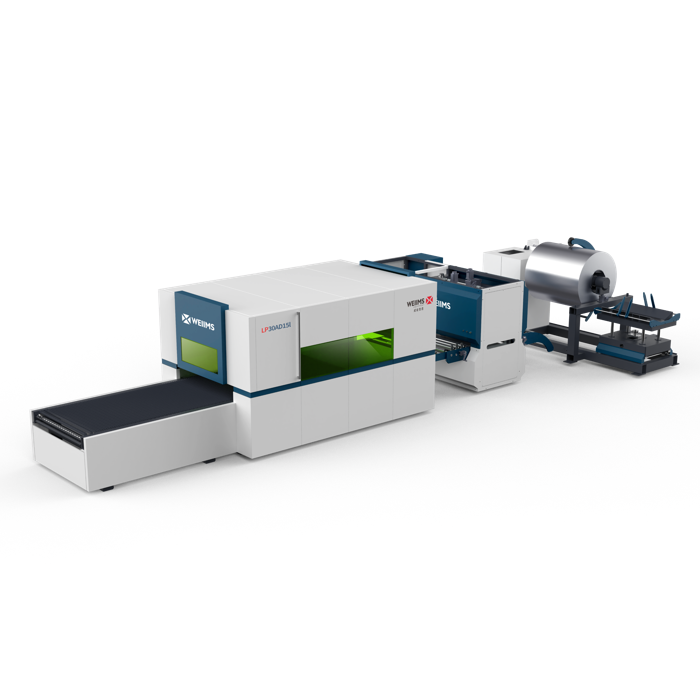

After market research and comparison, Hefeng company chose the edge bending center equipment of Zhejiang Weineng. The equipment adopts advanced numerical control technology, which can achieve high precision, high efficiency bending operation. Compared to the traditional manual bending method, the device has the following advantages:

High degree of automation: the edge bending center adopts advanced CNC system, which can realize automatic control, reducing the possibility of manual intervention and operation error.

High accuracy: the equipment uses high-precision sensors and advanced algorithm, which can achieve high-precision bending operation, reducing the error and the number of corrections.

High efficiency: compared with the traditional manual bending method, the edge bending center can realize fast and efficient bending operation, greatly improving the production efficiency.

Simple operation: the equipment has humanized operation interface and simple operation process, workers only need to conduct simple training to be skilled operation, human-machine interaction is good.

Good safety: the edge bending center adopts advanced safety protection measures and warning system, which can effectively reduce the risk of industrial accidents.

implement achievements

After the introduction of the edge bending center, the production efficiency of Hefeng company has been significantly improved. The bend work, which originally required several workers, now requires only a single edge bending center, and the product quality is more stable. Due to the high degree of automation of the equipment, the labor intensity of the workers has also been reduced, and more time and energy can be put into other production links. In addition, due to the high accuracy of the device, the product consistency and quality have also been greatly improved, and the customer satisfaction has also been improved.

The versatility of the center of the edge-bend

In practice, the edge bending center also has the following advantages:

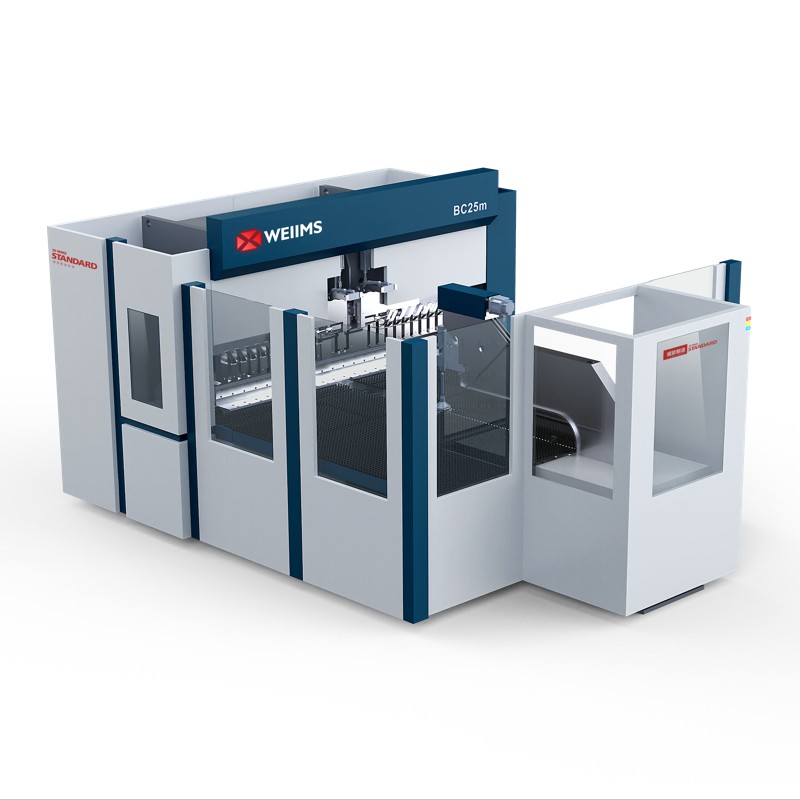

Strong scalability: the equipment has a strong scalability, and can be customized and modified according to different production needs, to meet the production requirements of different types of products. The mechanical arm can be installed to achieve full automatic production and greatly improve the production efficiency.

Simple maintenance: the equipment adopts modular design, maintenance is more convenient and fast, can reduce the maintenance cost and production downtime.

Energy saving and environmental protection: the edge bending center adopts advanced energy saving technology and environmental protection materials, which can reduce energy consumption and environmental pollution and meet the requirements of sustainable development.

Improve corporate image: the introduction of advanced production equipment can enhance the image and strength of the enterprise, enhance market competitiveness and brand awareness.

summary

By introducing edge bending center equipment, the company has successfully improved production efficiency and product quality, reducing the labor intensity of workers. This improvement enables the company to better meet the customer needs and enhance the market competitiveness. This also proves the application value of CNC technology in the field of sheet metal manufacturing. In the future development, Hefeng company will continue to introduce advanced production equipment and technology, constantly improve their own production capacity and technical level, to provide customers with better products and services.

The edge bending center has been tested by a variety of customer groups, with high stability, high precision, high stability, widely recognized by the customer group, and the price of raw materials and the fluctuation of transportation costs will change. If you need to buy the edge bending center, please contact us for the latest quotation (sales@weiims.ntesmail.com).

Zhejiang Weineng Intelligent Equipment Co., LTD., supply edge bending center, Zhejiang Weineng Intelligent Equipment Co., LTD. Is committed to the research and development of sheet metal flexible manufacturing technology,edge bending center can greatly improve production efficiency, improve production capacity, reduce the workload of production workers. Improve the degree of enterprise automation production.