Uncoiler: main components and performance characteristics

The main components of the uncoiler

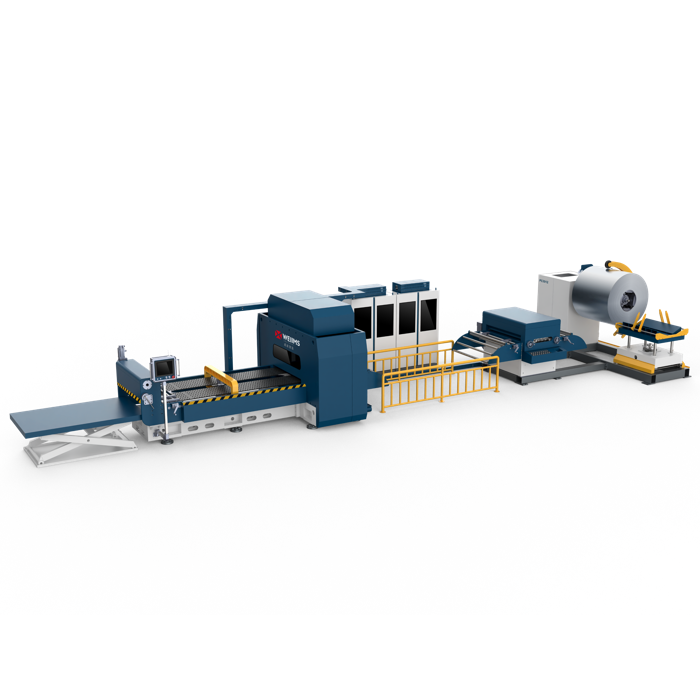

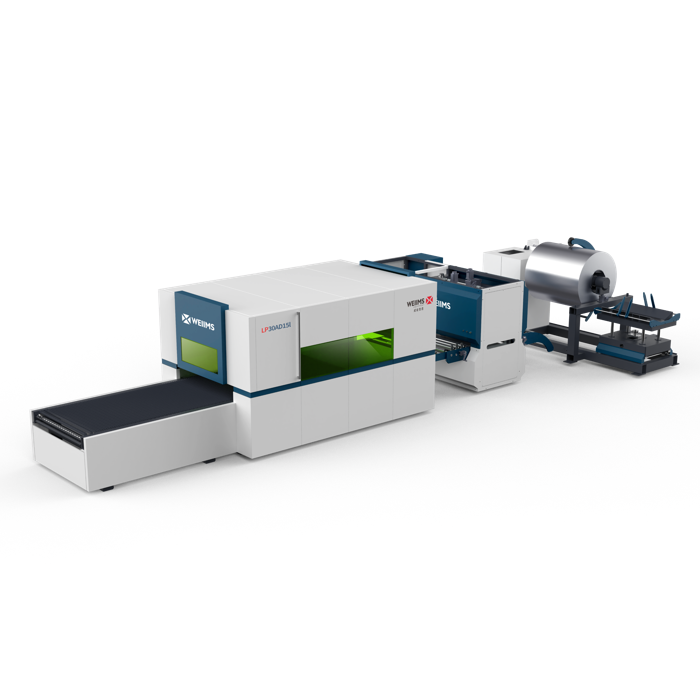

Uncoiler is one of the important equipment for sheet metal processing, which is mainly used to unfold the coil and feed it into the subsequent processing equipment. Uncoiler is mainly composed of the following parts:

Base: the base of the uncoiler is the support structure of the whole equipment, using high-quality steel welded together, with sufficient rigidity and stability, able to withstand the weight of the equipment and the impact of the processing process.

Reel: The reel is one of the main parts of the unwinder, which is used to support and rotate the metal coil. The reel is made of high quality steel with sufficient strength and wear resistance. According to different process requirements, the parameters such as diameter, width and length of the reel are different.

Transmission system: The transmission system is an important part of the unwinder and is used to drive the reel to rotate. The transmission system usually consists of a motor, reducer and bearings, etc. It is capable of achieving fast, stable and accurate rotary movements.

Clamping device: The clamping device is used to fix the metal coil and prevent it from moving or slipping off during the process. The tensioning device is usually hydraulic and can achieve fast, reliable and uniform tensioning force.

Guiding device: the guiding device is used to guide the metal coil into the subsequent processing equipment, made of wear-resistant materials, with sufficient rigidity and precision to ensure the smooth transport of the metal coil.

Safety protection device: safety protection device is used to protect the safety of the operator, usually including emergency stop button, protective cover and safety chain and so on.

The performance characteristics of each part of the unwinding machine

Reel: the reel is the core component of the unwinder, usually a hollow shaft, supported by two bearings in the gear box body. The material of the reel is made of high quality steel, and the surface is hardened to improve its wear resistance and fatigue resistance. The size and shape of the reel varies according to the requirements of the different processes, e.g. the diameter and length of the reel is usually larger in steel sheet processing and smaller in copper sheet processing.

Bearings and gears: Bearings and gears of unwinders are usually designed with high precision and low friction to ensure the stability and accuracy of the equipment. Bearings are usually rated at P5 or above, and gears are hardened and machined with high precision to achieve long term stable operation of the equipment.

Transmission system: The transmission system of the unwinder usually consists of motor, reducer and bearings. The motor is the main power source, the reducer is used to reduce speed and increase torque, bearings play a supporting and guiding role. The design of the transmission system needs to give full consideration to the stability and precision requirements of the equipment, in order to ensure the processing quality and productivity of metal sheets.

Tensioning device: The tensioning device is one of the important components of the uncoiler, used to fix the metal coil and prevent it from moving or slipping off during the process. Tensioning device is usually hydraulic, through the control of hydraulic pressure to adjust the size of the tensioning force. In order to ensure the stability and safety of the metal coil, the design and manufacture of the tensioning device are subject to strict quality control and safety assessment.

Guiding device: The guiding device is a component of the unwinder used to guide the metal coil into the subsequent processing equipment, and requires sufficient rigidity and precision to ensure the smooth transport of the metal coil. The guides are usually made of wear-resistant materials, such as high-quality steel or ceramic materials, and their surfaces are hardened to improve wear resistance and durability. In order to ensure the precision and stability of the conveyance of metal coils, the guides are designed and manufactured under strict quality control and safety assessment.

Safety Protection Devices: Safety protection devices are components of the unwinders that are used to ensure operator safety and require a high degree of reliability and safety. Safety protection devices usually include emergency stop buttons, guards and safety interlocks, etc., which can quickly cut off the power supply or take other emergency measures to protect the safety of the operator in the event of abnormalities or accidents in the equipment. In addition, the design and manufacture of safety protection devices undergo strict quality control and safety assessment to ensure a high degree of reliability and safety.