The working principle of automatic tool change in bending

With the rapid development of industrial automation, bending centre as an important equipment in the field of metal processing, its automatic tool changer function plays a key role in improving production efficiency and processing accuracy. This paper introduces the basic structure, working principle and application in actual production of automatic tool changing system of bending centre, and analyses the key technology in the process of automatic tool changing.As an important equipment in the modern metal processing industry, bending centre is widely used in the bending of various metal sheets. In the bending process, according to the requirements of different plate materials, thicknesses and bending angles, tools need to be changed frequently. The traditional manual tool change is inefficient and cannot meet the needs of modern production. Therefore, the emergence of automatic tool changing system has become the key to upgrade the technology of bending centre.

Overview of automatic tool changer system for bending centre

The basic structure of the automatic tool changer system

Automatic tool changer system mainly consists of tool magazine, tool changer, control system and other components. Among them, the tool magazine is responsible for storing a number of different specifications of the tool, tool changer is responsible for automatically selecting and replacing the tool when needed, and the control system is responsible for the coordination and control of the entire tool changing process.

The working principle of automatic tool changer system

The working principle of the automatic tool changing system can be divided into the following steps:

Tool identification: The system identifies the tool to be changed by recognising the number or type of tool currently required.

Tool Selection: The tool changing mechanism selects the corresponding tool from the tool magazine according to the instruction issued by the control system.

Confirmation of the completion of the tool change: the system detects whether the new tool is installed in place, and confirms the completion of the tool change process, ready for the next bending operation.

Third, the key technologies in the process of automatic tool change

Tool identification and positioning technology: In order to ensure the accuracy and efficiency of automatic tool change, tool identification and positioning technology is the key. The system needs to be able to accurately identify the tool number, type and storage location, to ensure that when needed to quickly select the correct tool.

Optimised design of tool changer: The tool changer is the core component of the automatic tool changer system, and its reasonable design directly affects the speed and accuracy of tool changing. By optimising the mechanical structure of the tool changer, the transmission mode and the control system, the stability and efficiency of the tool changing process can be improved.

Intelligent upgrade of control system: With the continuous development of industrial automation, the intelligent upgrade of control system has become an inevitable trend. Through the introduction of advanced algorithms and control logic, it can realise the precise control of the automatic tool changing process and further improve the speed and precision of tool changing.

Application of automatic tool changer system in bending centre

Improve production efficiency: automatic tool changer system can significantly reduce the involvement of manpower to achieve rapid tool replacement, thereby shortening the production cycle and improving production efficiency.

Guarantee of processing accuracy: automatic tool changer system can effectively guarantee the accuracy and stability of bending processing through accurate tool identification, positioning and replacement process.

Reduced operating difficulty: the automatic tool changer system simplifies the operation process and reduces the technical requirements for operators, enabling more people to easily master the operating skills of the bending centre.

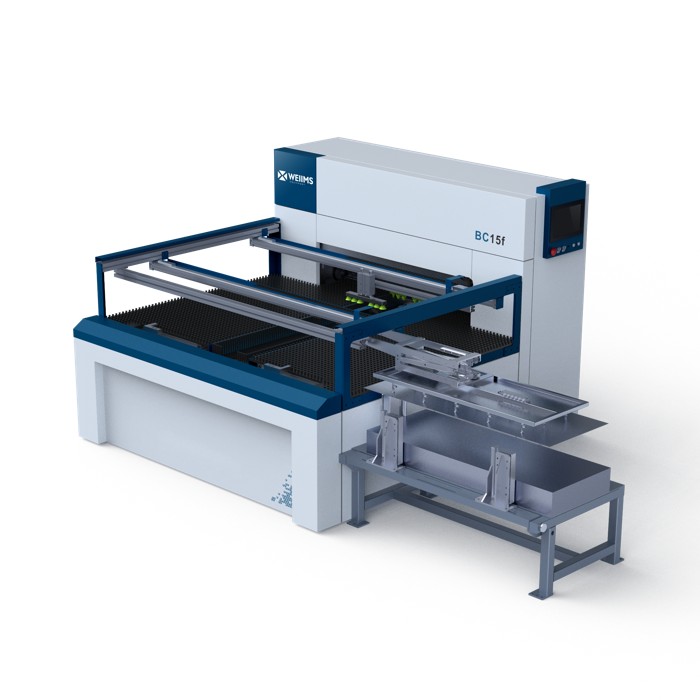

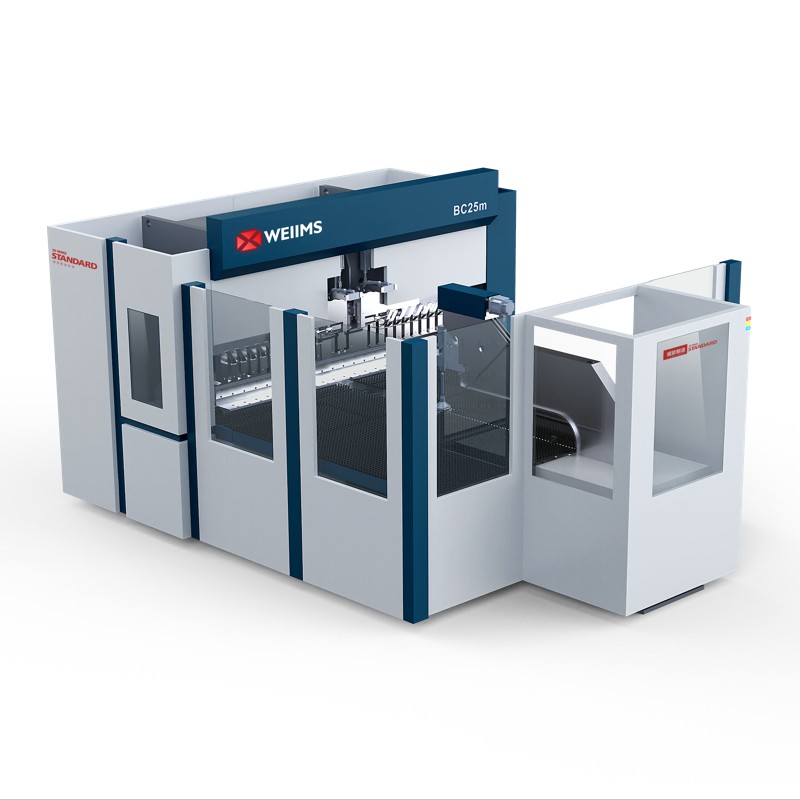

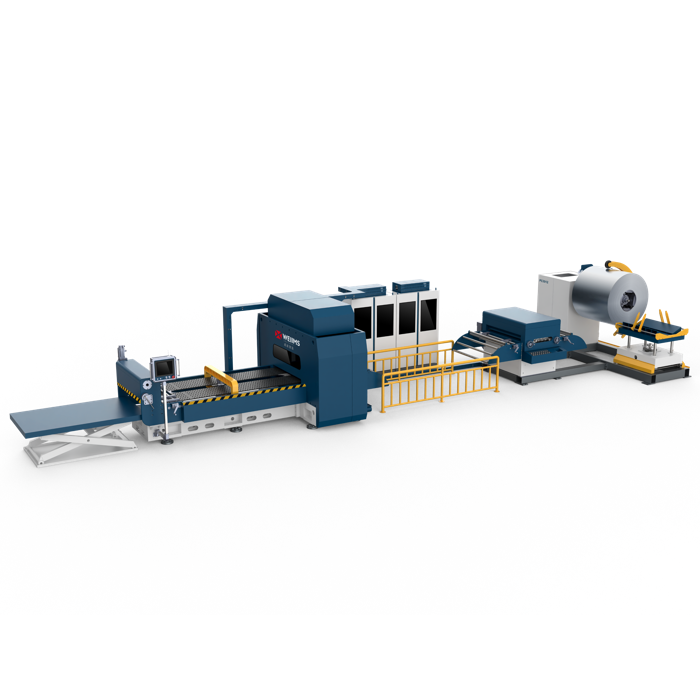

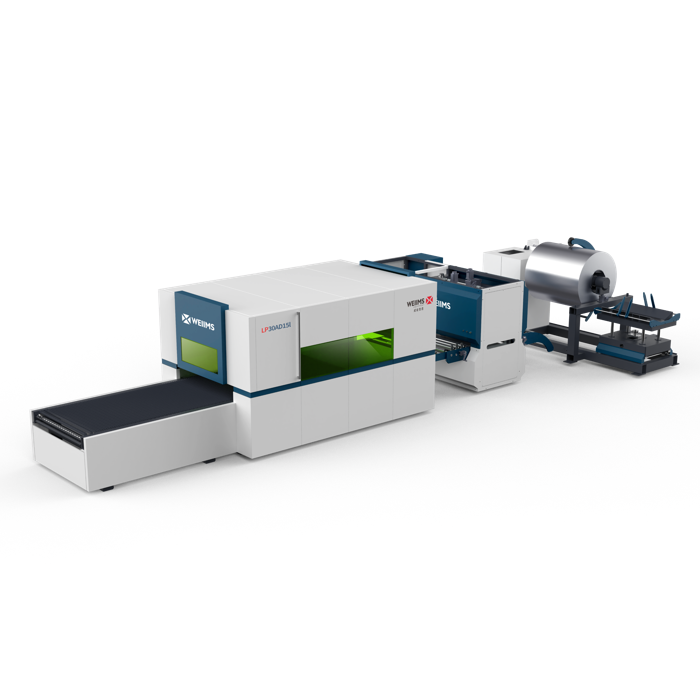

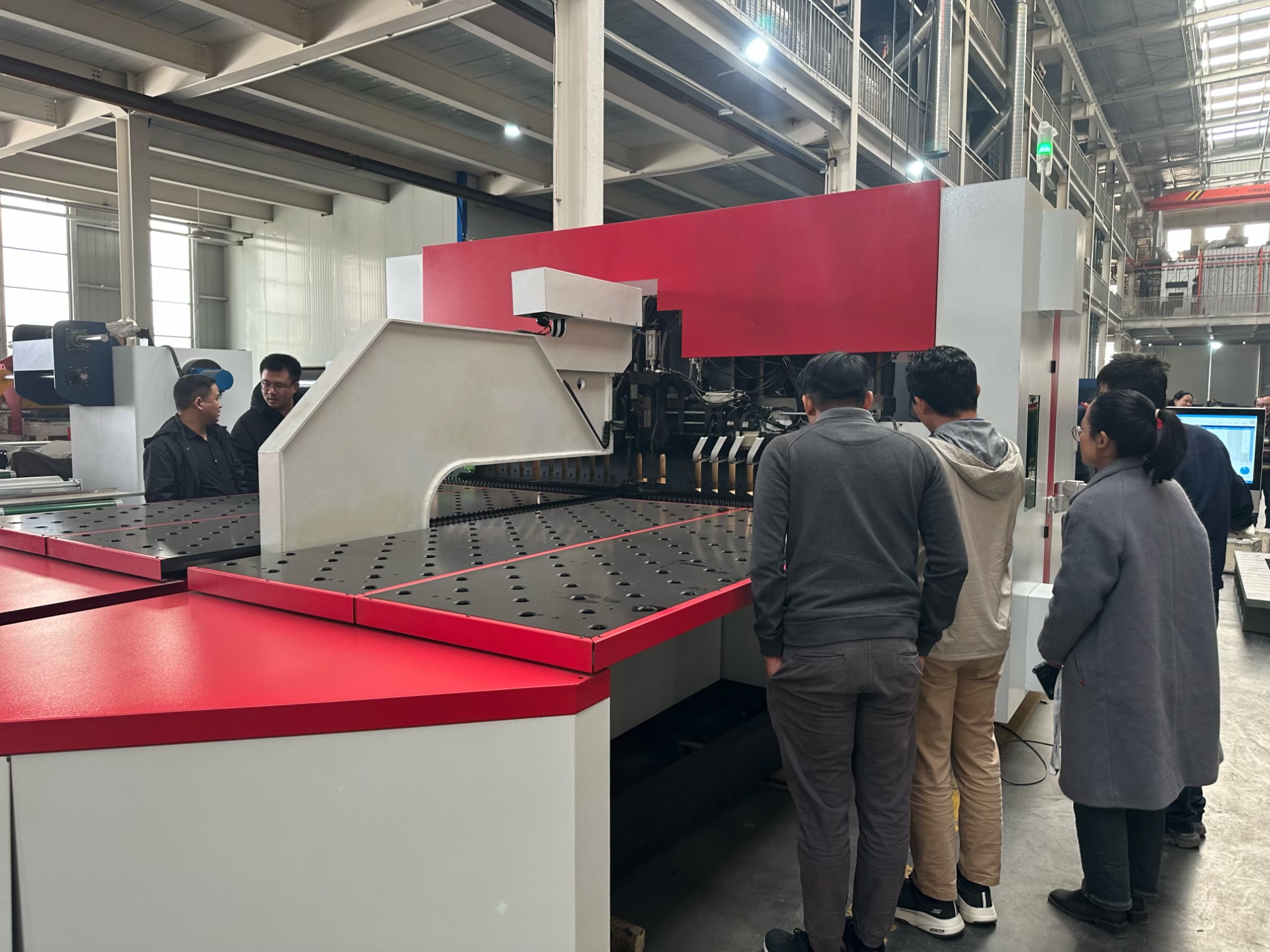

Bending center through a variety of customer groups tests, with high stability, high precision, high stability widely recognized by customer groups, by the impact of raw materials and transportation costs, the price will change if you need to buy a Bending center, please get in touch with us to get the latest quotation (sales@weiims.ntesmail.com).

Zhejiang Weiims Intelligent Equipment Co., LTD. supplies a Bending center. Zhejiang Weiims Intelligent Equipment Co., Ltd. is committed to engaging in the research and development of sheet metal flexible manufacturing technology; multilateral bending centers can greatly improve production efficiency, improve production capacity, and reduce the workload of production workers. Improve the degree of enterprise automation production.