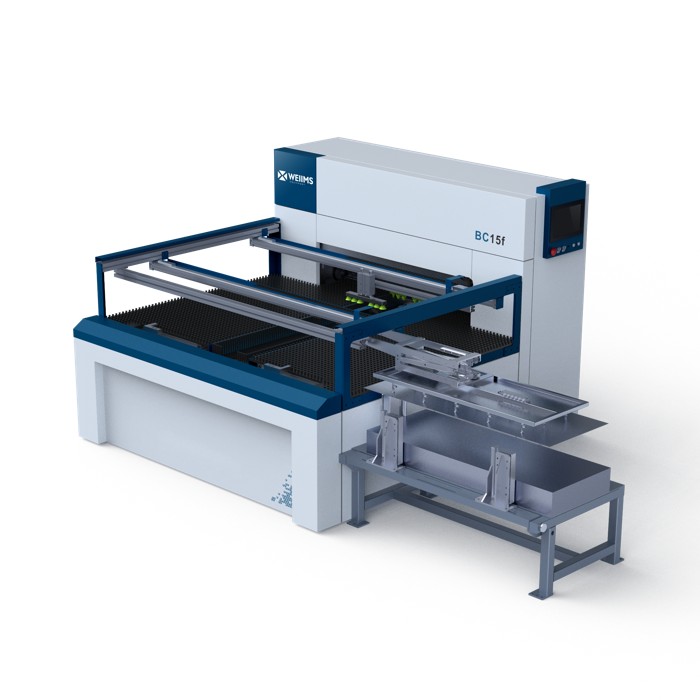

Metal stamping machine: principle, performance characteristics and widely used areas of exploration

Metal stamping press is a kind of equipment for stamping and forming metal sheets by using moulds, which has the advantages of high efficiency, precision, good repeatability and so on. With the continuous development of modern industry, metal stamping technology in the manufacturing industry is becoming more and more prominent, and has become an indispensable means of production in many industries.The basic principle of metal stamping machine

The basic principle of metal stamping machine is to make the metal sheet plastic deformation under the action of the mould through pressure, so as to obtain the required shape and size of the parts. Stamping process mainly includes the following steps:

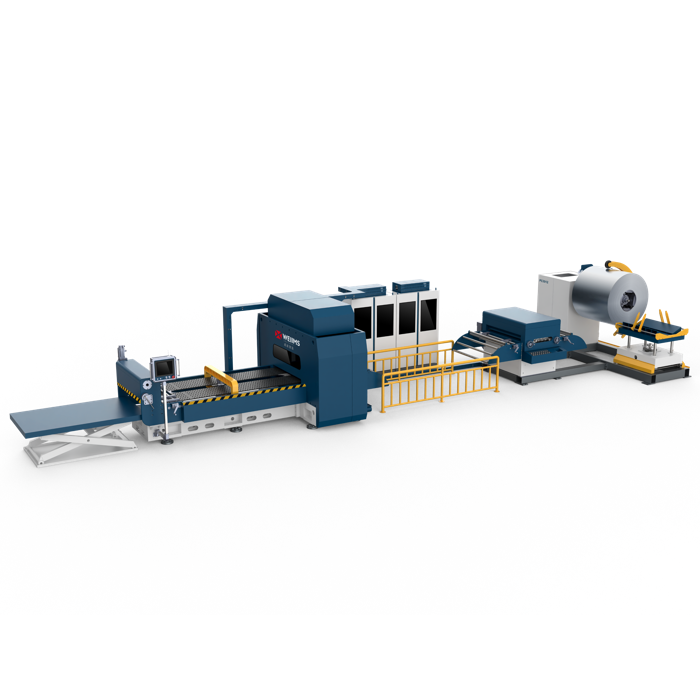

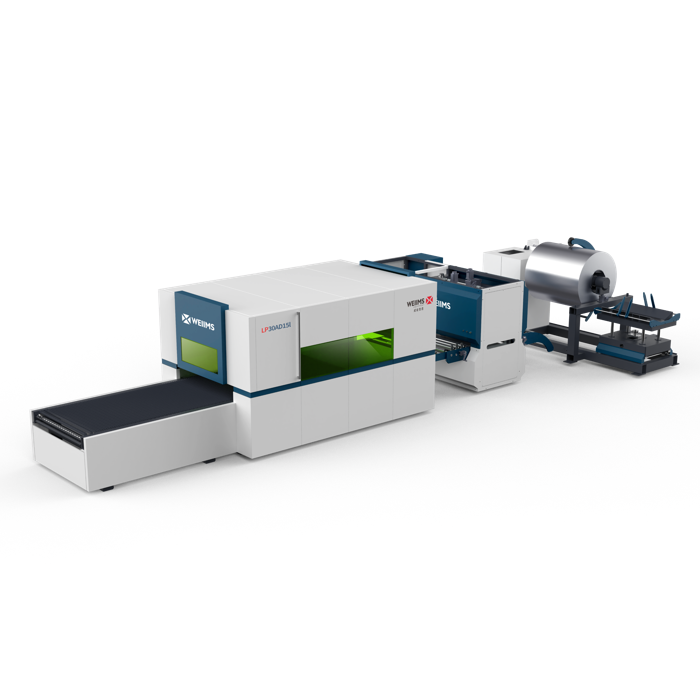

Feeding: the sheet metal is fed into the working area of the press.

Positioning: the positioning device ensures the exact position of the sheet metal during the stamping process.

Stamping: The upper and lower moulds of the stamping press close together, exerting pressure on the sheet to cause it to undergo plastic deformation.

Discharging: after stamping is completed, the finished parts are taken out from the mould and sent out by the discharging device.

The performance characteristics of metal stamping machine

High efficiency: metal stamping press can realise high-speed continuous stamping, which greatly improves the production efficiency.

High precision: the precise manufacture of moulds and the precise control of presses ensure the high precision of stamped parts.

High repeatability: the same mould can be used for mass production of parts with the same specifications, which ensures the consistency of the products.

High material adaptability: it is suitable for the stamping processing of many metal materials, such as steel, aluminium, copper and so on.

Energy saving and environmental protection: compared with traditional mechanical processing, stamping processing has lower energy consumption and less material waste.

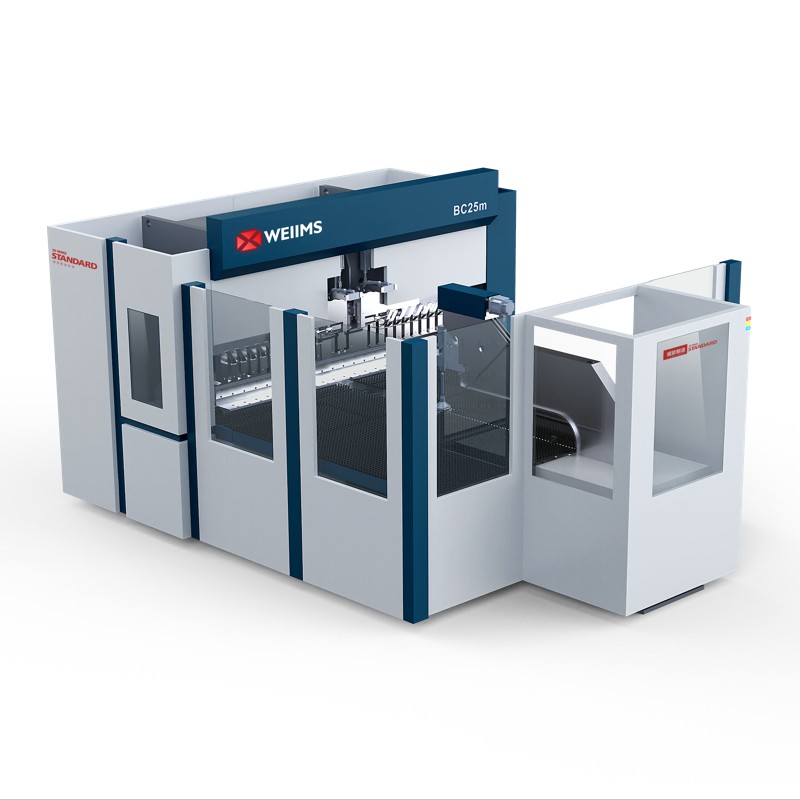

High degree of automation: it can be used with automatic feeding and discharging devices and testing equipment to achieve fully automated production.

The application scope of metal stamping machine

Automobile industry: metal stamping parts are used in large quantities in automobile manufacturing, such as body covering parts and chassis parts. Stamping technology for the automotive industry to provide efficient, low-cost production solutions.

Electronic industry: metal shells, connectors, terminals and other parts in electronic products are mostly made through stamping. Stamped parts have the advantages of compact structure, light weight, good electrical conductivity and so on.

Home appliance industry: metal shells, brackets, heat sinks and other parts of home appliances are widely produced by stamping technology. Stamping not only improves production efficiency, but also reduces product costs.

Hardware industry: Hardware products such as locks, tools, kitchen utensils, etc., the production process of which makes extensive use of stamping technology. Stamped parts are characterised by high precision, high strength and good wear resistance.

In addition to the above industries, metal stamping presses are also widely used in aerospace, shipbuilding, military and other fields, which provide manufacturing support for key components in these industries.

The development trend of metal stamping machine

With the continuous progress of science and technology and the rapid development of industry, metal stamping presses are developing in the following directions:

Large-scale and high-speed: in order to meet the demand for large-scale production, stamping presses are being developed in the direction of large-scale and high-speed, in order to improve production efficiency and reduce production costs.

Intelligent and automated: with the help of advanced control technology and sensor technology, to achieve intelligent and automated stamping presses, reduce manual intervention, improve production quality and efficiency.

Precision and multifunctionality: With the improvement of product requirements for precision and function, press machines are developing towards precision and multifunctionality to meet the processing needs of complex parts.

Greening and energy-saving: Environmental protection and energy-saving have become the focus of global attention, and stamping presses are paying more and more attention to greening and energy-saving in the design and manufacturing process, in order to reduce energy consumption and environmental pollution.

As an efficient and precise metal processing equipment, metal stamping presses play a pivotal role in modern industry. This paper describes in detail the basic principle of metal stamping press, its performance characteristics and its application scope in various industries, and discusses its development trend. With the continuous progress of science and technology and the rapid development of industry, metal stamping press will usher in a broader development space and application prospects.