Important components of a three-in-one feeding machine

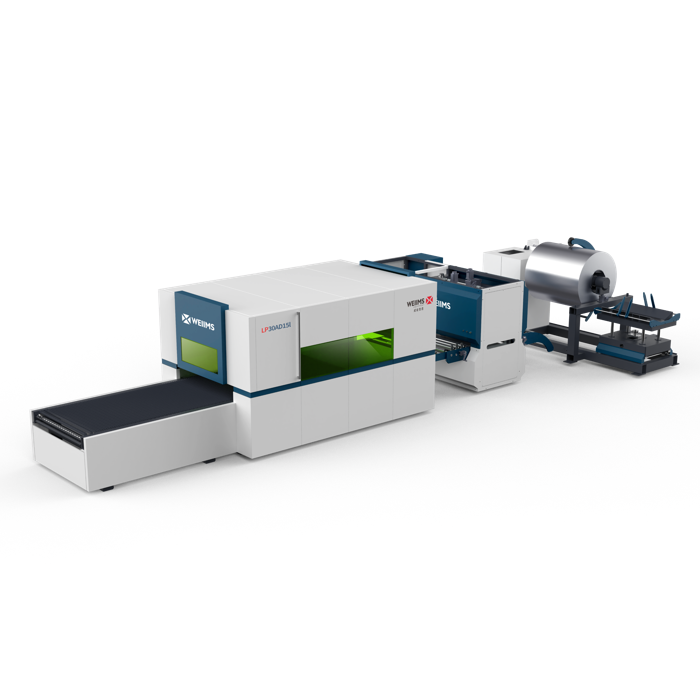

Characteristics and advantages of the coil material frame

As the first part of the three-in-one feeding machine, the material rack mainly undertakes and supports the role of the material. Its features and advantages are as follows:

Material Support and Positioning: The roll material rack can effectively support the material and prevent it from being offset or twisted during the feeding process. At the same time, the precise positioning system can ensure the accuracy and consistency of the material during feeding.

Adaptable: The roll feeder can adapt to different specifications and types of rolled materials, such as materials of different widths, thicknesses and materials. This flexibility allows the 3-in-1 feeder to be used in a wide range of processing applications.

Ease of operation: Roll holders are often designed with operator convenience in mind. For example, loading and unloading materials is very simple and fast, preventing the roll material to the dolly, and then remotely controlling the dolly and setting the roll material to the shaft of the frame, which helps to reduce the operation time and labor intensity.

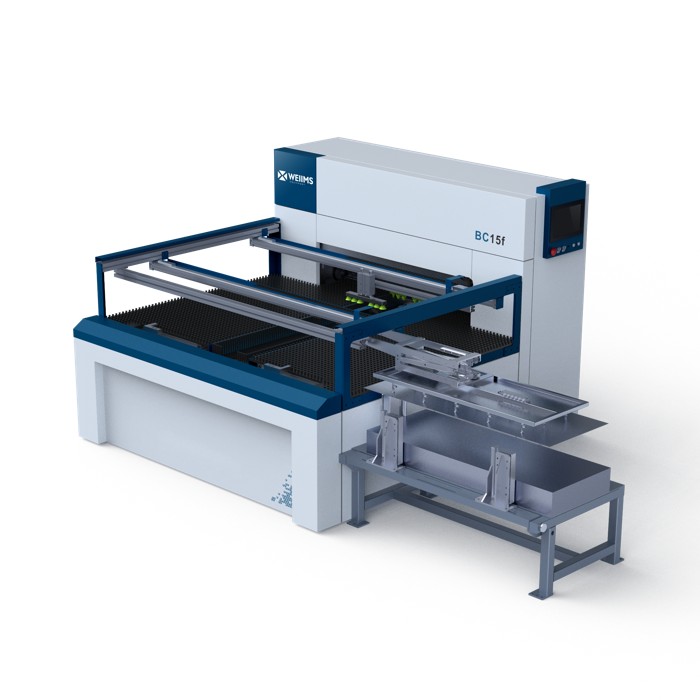

The characteristics and advantages of the leveling machine

The leveling machine is one of the core parts of the three-in-one feeding machine, which is mainly responsible for leveling the material. Its features and advantages are as follows:

High-precision leveling: the leveling machine adopts advanced leveling technology, which can realize a high-precision leveling effect, ensure the flatness of the material, and reduce the problems of bending and warping of the material.

Automatic control: the leveling machine adopts an automatic control system, which can realize automatic detection and control and improve the accuracy and stability of leveling.

High performance: The leveling machine is characterized by high performance, which can quickly complete the leveling process of the material and reduce the leveling time and production cycle.

Easy to operate: the operation of the leveling machine is simple and convenient, and it can quickly adjust and set the parameters, reducing the operating time and error.

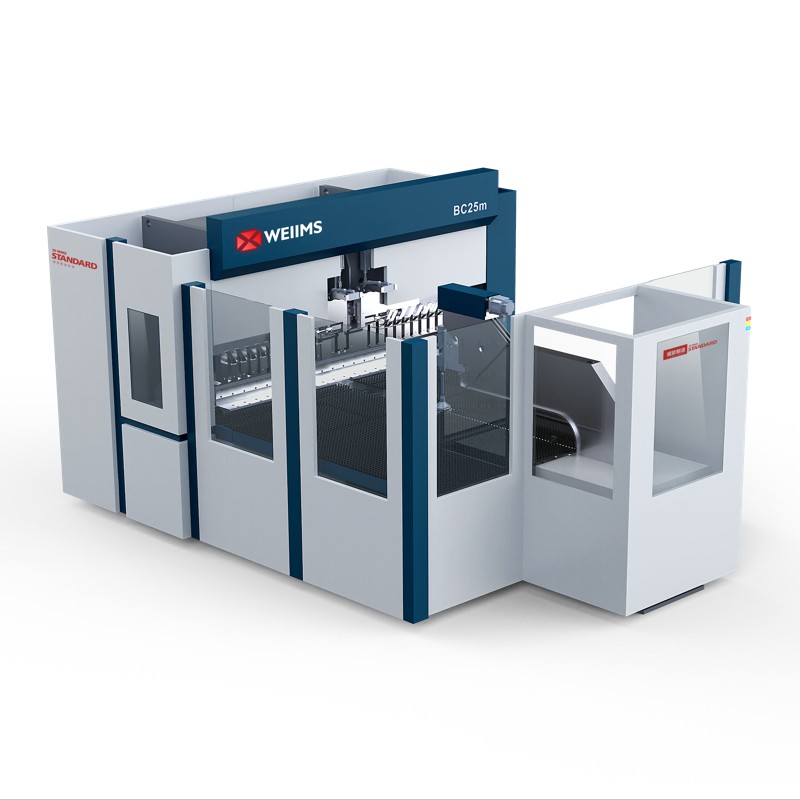

The characteristics and advantages of the feeding machine

The feeder is the last part of the three-in-one feeding machine and is mainly responsible for conveying the material after leveling. Its features and advantages are as follows:

High-speed conveying: the feeder adopts a high-speed conveyor belt design, which can realize high-speed conveying and improve production efficiency.

Accurate positioning: the feeder adopts a high-precision positioning system, which can realize accurate positioning and ensure stable material conveying during processing.

Multi-functional conveying: the feeder can be adjusted multifunctionally according to different materials and processing needs, such as adjusting the speed and tension of the conveyor belt to meet different production needs.

Easy to operate: the operation of the feeding machine is simple and convenient, and it can quickly adjust and set the parameters, which reduces the operation time and error.

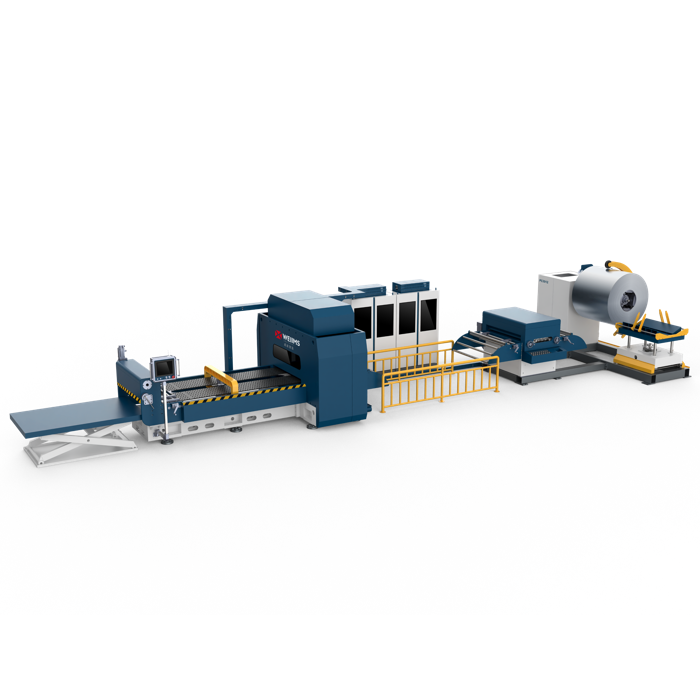

The advantages of the three-in-one feeding machine after the composition of the advantages of the three-in-one feeding machine:

The 3-in-1 feeding machine organically combines the material rack, leveler, and feeder together, giving full play to their respective advantages and realizing efficient, accurate, and automatic material conveying and processing. Its main advantages are as follows:

Improvement of production efficiency: The 3-in-1 feeding machine significantly improves production efficiency and reduces production time and cost through automated control, high-speed conveying, and other technical means.

Accurate positioning and leveling: Through a high-precision positioning system and advanced leveling technology, the 3-in-1 feeding machine can ensure the accurate positioning and leveling of materials before processing, which improves processing accuracy and quality.

Automation control: The 3-in-1 feeding machine adopts an automation control system, which realizes the functions of automatic detection, adjustment and control, reducing manual intervention and errors.

Multi-functional applicability: The 3-in-1 feeding machine can be adjusted multifunctionally according to different materials and processing needs to meet a variety of production requirements, which improves the utilization rate and applicability of the equipment.

Easy to operate and maintain: the operation of the three-in-one feeding machine is simple and convenient, easy to maintain and repair, reducing the difficulty of operation and maintenance costs.

High reliability: The three-in-one feeding machine adopts high-quality parts and materials with high reliability and stability after strict quality control and testing.

Energy saving and environmental protection: Three-in-one feeding machines in the design and manufacturing process give full consideration to energy saving and environmental protection requirements, the use of advanced energy-saving technologies, and environmentally friendly materials, in line with the current trend of sustainable development of society.

Reduce costs: three-in-one feeding machines can reduce production costs and improve production efficiency, which is also an obvious advantage. It can reduce labor costs, energy costs, equipment costs, and other aspects of expenditure, thereby creating greater economic benefits for the enterprise.

Improve product quality: Because the three-in-one feeding machine has the characteristics of accurate positioning and high flatness, using it can improve the quality and appearance of the product. This helps to enhance the competitiveness of the enterprise's products and win more customers' trust and favor.

Fast delivery: using a 3-in-1 feeding machine can shorten the production cycle and delivery time. It can handle a large amount of materials in a short period of time and quickly complete processing tasks, thus meeting customers' demand for fast delivery. This helps to improve customer satisfaction and the market reputation of the company.

Integrated design: The 3-in-1 feeder adopts an integrated design concept, which organically combines several functional modules together. This design not only simplifies the structure and operation process of the equipment but also improves its stability and reliability. At the same time, the integrated design is also conducive to the maintenance and upgrading of the equipment.

In addition to the advantages mentioned above, the three-in-one feeder has the following significant features and additional advantages in practical applications:

Flexibility and modular design

A three-in-one feeding machine usually adopts a modular design, which means that enterprises can choose different modules to combine according to their own production needs. This flexibility makes the equipment easily adapt to a variety of production environments and processing requirements, whether it is small batch production or large-scale production lines, and can achieve efficient and stable feeding.

Humanized design

Three-in-one feeding machines in the design of the operator's habits and safety needs are fully taken into account. The equipment is usually equipped with an intuitive operator interface and convenient control buttons so that the operator can easily get started and quickly master the various functions of the equipment. At the same time, the equipment also adopts multiple safety measures to ensure the safety of the operator in the process of use.

Space saving and a simplified layout

Because the 3-in-1 feeder integrates the material frame, leveler and feeder together, it can effectively save space on the production site. Compared with the traditional split equipment, the 3-in-1 feeder has a more compact layout and smaller footprint, which is conducive to enterprises improving the utilization rate of the production site and the overall aesthetics.

Through its unique design and functional integration, the 3-in-1 feeder brings many advantages and values to enterprises. It not only improves production efficiency and quality but also reduces production costs and maintenance difficulties; at the same time, its flexibility and modular design enable companies to easily respond to market changes and changes in production requirements.

3-in-1 feeder through a variety of customer groups tests, with high stability, high precision, high stability widely recognized by customer groups, by the impact of raw materials and transportation costs, the price will change if you need to buy a 3-in-1 feeder, please contact us to get the latest quotation (sales@weiims.ntesmail.com).

Zhejiang Weiims Intelligent Equipment Co., LTD. supplies a 3-in-1 feeder. Zhejiang Weiims Intelligent Equipment Co., Ltd. is committed to engaging in the research and development of sheet metal flexible manufacturing technology; a 3-in-1 feeder can greatly improve production efficiency, improve production capacity, and reduce the workload of production workers. Improve the degree of enterprise automation production.