How can we solve the problem of inaccurate feeding or partial feeding of a 3-in-1 feeder?

The three-in-one feeder is one of the widely used equipment in the modern manufacturing industry, especially in metal processing, stamping, and welding. It can efficiently and accurately convey materials, which is the key to the normal operation of the production line. However, in the actual use of the process, sometimes there will be feeding inaccurate or biased material problems, which not only affects the production efficiency and product quality but also may cause damage to the equipment. Therefore, the three-in-one feeding machine feeding inaccurate or biased material problems for in-depth analysis and putting forward the corresponding solution is crucial.

The working principle and structure of the three-in-one feeding machine

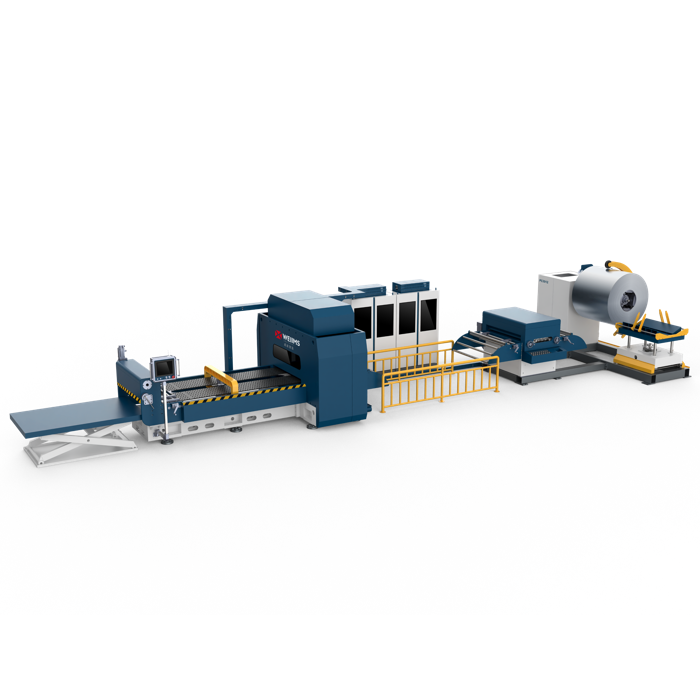

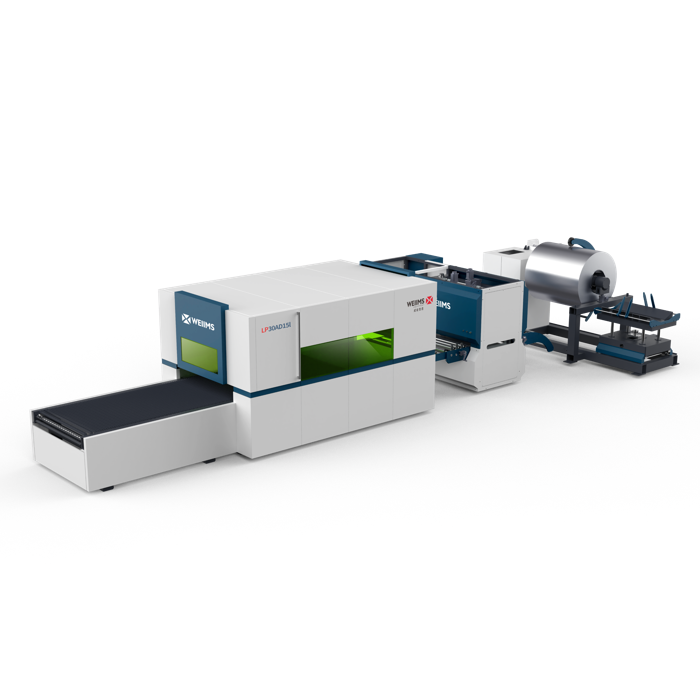

Unwinding part: Unwinding machine is a support platform that fixes the material roll on the expanding part of the spindle of the material frame and supports the inner diameter of the material roll. During automatic operation, the spindle rotates intermittently through the material ring control command. It includes a spindle expansion part, pressure arm part, limit wheel part, and material ring control part.

Leveling section: The leveling feeder is a device that delivers a certain amount of bending deformation to the press through the feed rollers after the coil supported on the unwinder forms the material ring. In addition, the leveling feeder is designed and manufactured as a device for the press line with the main purpose of eliminating coil curling. When there is partial elongation of the material, sometimes it cannot be completely corrected. The feeding mechanism is located at the end of the leveling mechanism. After leveling, the belt roller rotates synchronously to feed the material, and the input length is controlled by PLC to achieve the feeding.

Feeding part: The feeding device, on the other hand, drives the feeding rollers through servo motors to feed the material to the stamping equipment. In addition, the blocking wheel, pressure wheel and tension controller also play a key role.

Feeding inaccurate or biased material problems causes analysis

Mold positioning problem: In the process of feeding, the improper setting of the mold positioning pin causes the material to deviate from the center, which affects the accuracy and stability of feeding.

Coil quality problems: coil burrs are serious, bending, uneven or different widths, and other quality problems may lead to deviation in the feeding process.

Improper adjustment of stopper wheel: Improper adjustment of the stopper wheel of the 3-in-1 feeder can lead to material deviation. Including the unwinding part of the blocking device, leveling the feeding part of the width of the guide wheel, and the width of the discharge wheel not adjusted properly, which will lead to uneven compression strength of the pressure device, which will lead to feeding deviation.

Problems with the machine itself, such as the drum not being centered, servo abnormality, gears or foreign objects in the drum, etc., may lead to inaccurate feeding.

Insufficient pressure of external air source: The pressing force of the pressing cylinder is not enough, resulting in incorrect feeding or relaxation time and affecting the accuracy of feeding.

Practical operation problems: Insufficient experience of the operator in equipment adjustment and parameter setting may also lead to inaccurate feeding or biased material.

Solution and Implementation Steps

Adjust the mold positioning pins: According to the material characteristics and thickness, re-adjust the position and angle of the mold positioning pins to ensure that the material does not shift during the leveling process.

Checking and replacing rolls: Check the quality of existing rolls and replace those that do not meet the standard to ensure that the quality of the material meets the requirements.

Adjust the blocking wheel: according to the instructions for the use of the equipment and the actual production situation, adjust the position and angle of the blocking wheel to ensure that the material remains stable in the conveying process.

Check and repair the machine: Carry out a comprehensive inspection of the machine, especially the key parts such as rollers, servo system, gears, rollers, etc., and repair or replace them in time if any abnormality is found.

Check the pressure of the air source: Make sure the pressure of the external air source is sufficient to meet the requirements of the normal operation of the machine. If the pressure of the air source is found to be insufficient, the air source should be adjusted or replaced in time.

Training of operators: Strengthen the training of operators, improve their familiarity with the equipment and operating skills, and ensure that they can operate the equipment correctly and skillfully.

Regular maintenance: formulate and implement a regular maintenance plan, inspect, clean, lubricate and adjust key parts to ensure the stability and durability of the equipment.

The solution can be adjusted and optimized in conjunction with the actual production situation to achieve better results.

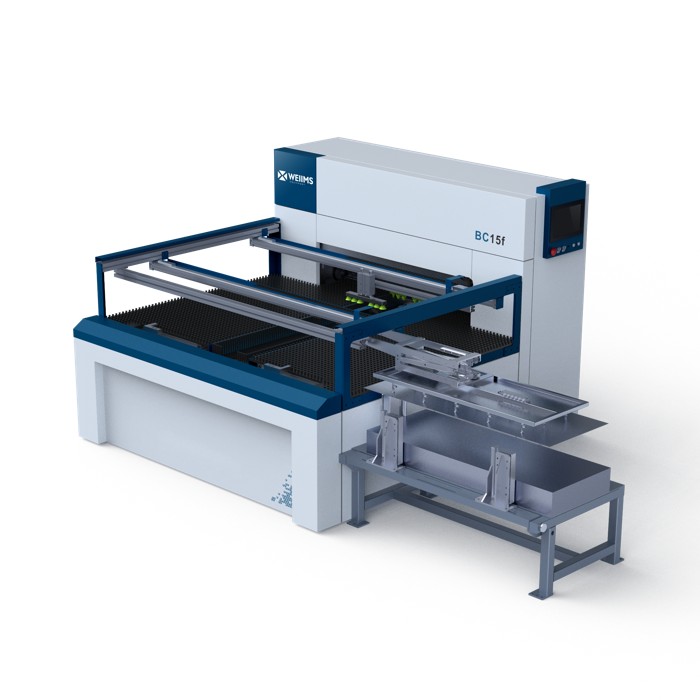

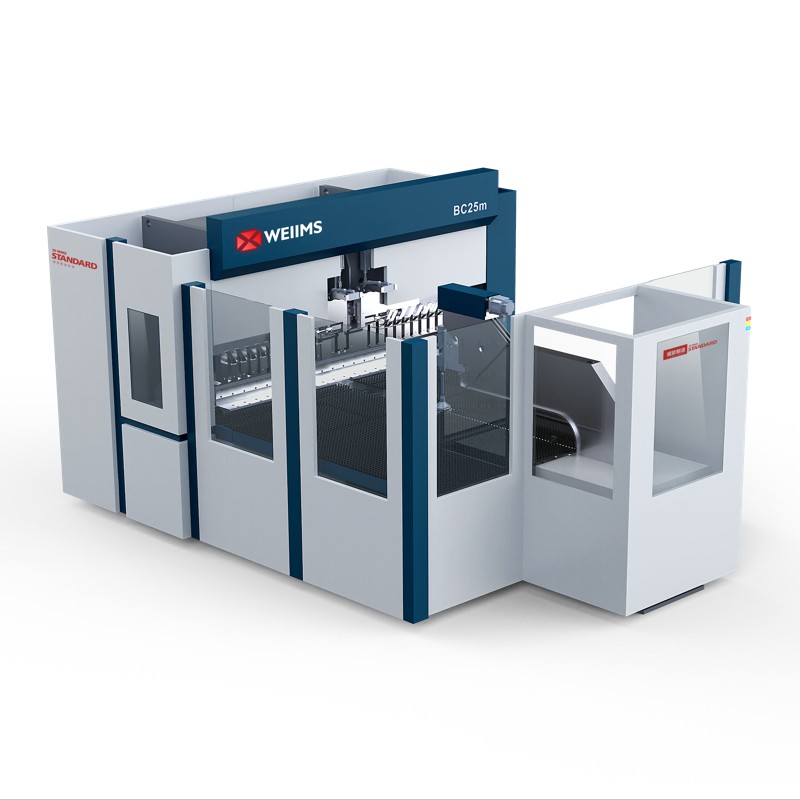

3-in-1 feeder through a variety of customer groups tests, with high stability, high precision, high stability widely recognized by customer groups, by the impact of raw materials and transportation costs, the price will change if you need to buy a 3-in-1 feeder, please contact us to get the latest quotation (sales@weiims.ntesmail.com).

Zhejiang Weiims Intelligent Equipment Co., LTD. supplies a 3-in-1 feeder. Zhejiang Weiims Intelligent Equipment Co., Ltd. is committed to engaging in the research and development of sheet metal flexible manufacturing technology; a 3-in-1 feeder can greatly improve production efficiency, improve production capacity, and reduce the workload of production workers. Improve the degree of enterprise automation production.