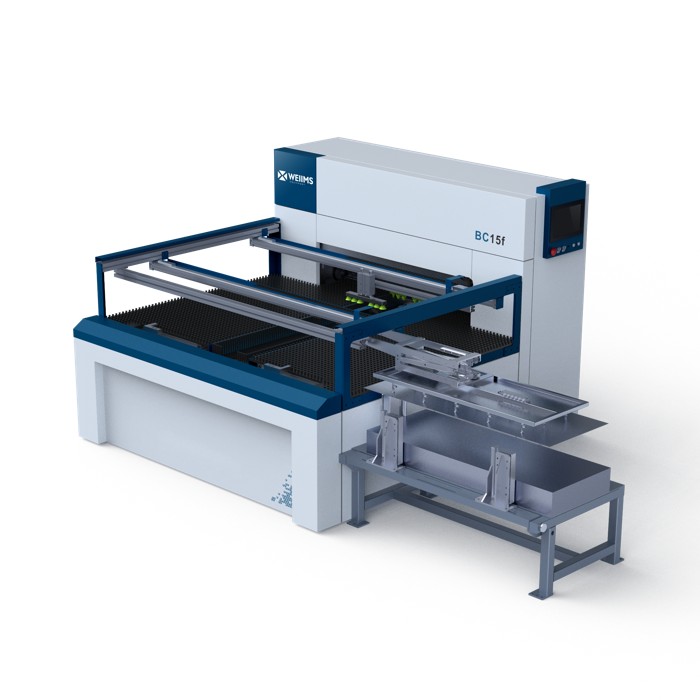

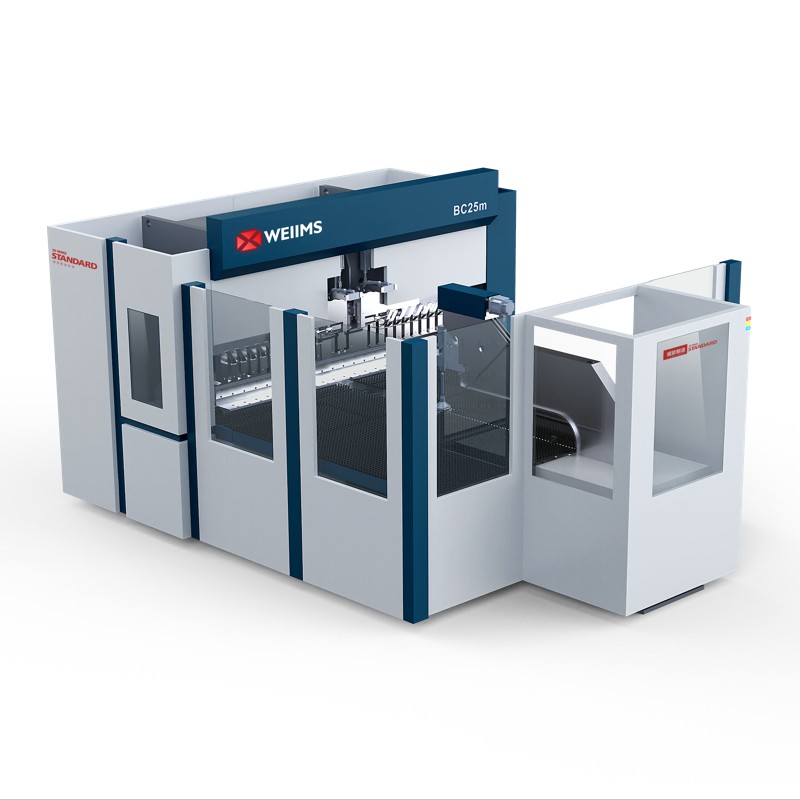

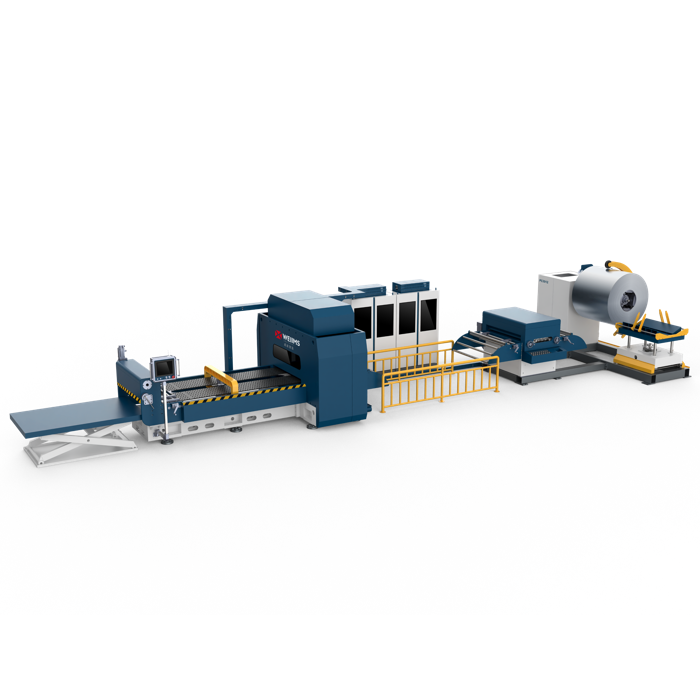

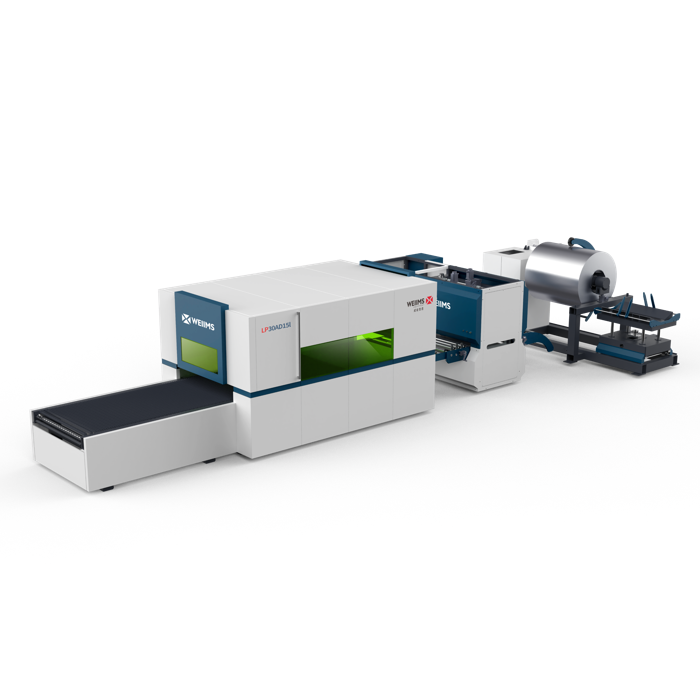

Edge bending center is the key equipment to improve the quality and efficiency of steel furniture

With the development of industrial automation and market competition, more and more manufacturing industries began to use advanced equipment to improve production efficiency and product quality. The steel furniture industry, as a member of the traditional manufacturing industry, is also constantly exploring new technologies and equipment to improve production efficiency and product quality. Among them, the edge bending center as a high-efficiency, high-precision processing equipment in the steel furniture industry is playing an increasingly important role.

The working principle and characteristics of the edge-bending center

Edge bending center is an integrated CNC technology, mechanical transmission, electrical control and other technologies of composite processing equipment. Its working principle is mainly driven by high-precision servo motors to achieve fast and accurate bending operation. At the same time, the edge bending center also has the characteristics of high rigidity and high stability, which can ensure bending accuracy and repeatability and effectively improve the quality of products and production efficiency.

The features of the edge bending center mainly include the following aspects:

High efficiency: In the traditional production line, manual bending operation is not only inefficient but also difficult to ensure accuracy, often requiring repeated adjustments and corrections. The wrench edge bending center, through CNC technology, can quickly and accurately complete the bending operation, greatly improving production efficiency. This means that companies can shorten the production cycle and quickly respond to market demand while reducing labor costs and production costs. In addition, the efficiency of the toggle bending center is also reflected in its flexibility and adjustability. Through simple parameter setting and programming operations, companies can quickly adjust the parameters and production mode of the equipment according to different product needs and production requirements, realizing rapid production changeover and diversified production.

High precision: Traditional bending operations often result in large dimensional errors due to limited precision, affecting the overall quality and appearance of the product. The edge bending center adopts high-precision servo motors and a mechanical transmission system, which can realize high-precision bending operation and effectively guarantee the quality and dimensional accuracy of the products. This not only meets the customer's demand for high-quality products but also improves the added value and market competitiveness of the products. At the same time, high precision also means less scrap and defective products, reducing production costs and waste.

Convenience of operation: The CNC programming technology of the wrench edge bending center makes the operation easy and efficient. Workers only need to complete the bending processing of steel furniture parts of different shapes and specifications through simple parameter setting and programming operations. This greatly reduces the production preparation time and adjustment time, and improves production efficiency. Meanwhile, the equipment operation interface is friendly and easy to learn and use, which lowers the technical threshold of workers and reduces training time and cost.

Easy maintenance: the design of the wrench edge bending center is simple, and the components are easy to disassemble and replace, which is convenient for the daily maintenance and repair of the equipment. In addition, the equipment has a low failure rate, which can ensure stable operation for a long time.

Environmental protection and energy saving: edge bending center using advanced servo motors and drive systems to achieve low noise and low energy consumption operation, in line with the requirements of modern manufacturing environmental protection and energy saving.

The advantages of the application of edge bending centers in the steel furniture industry

Edge bending centers in the steel furniture industry advantages are mainly reflected in the following aspects:

Improve production efficiency: the high efficiency of the edge bending center can greatly improve the production efficiency of steel furniture, shorten the production cycle, and reduce production costs. At the same time, the stability and reliability of the equipment can also reduce equipment failure and maintenance time and further improve production efficiency.

Enhance product quality: The high precision of the edge bending center can effectively ensure the quality of steel furniture products and improve the dimensional accuracy and appearance quality of the products. This not only meets customer demand but also enhances the added value of the product and market competitiveness.

Promote technological innovation: the application of edge bending centers can promote technological innovation and technological progress in the steel furniture industry. Through the introduction of advanced equipment and technology, enterprises' technical level and innovation ability are improved, and the overall development of the industry is further promoted.

Adapt to market demand: With the continuous improvement of consumer demand for furniture quality and personalization, the steel furniture industry needs to continue to introduce new products and personalized products. The efficiency and flexibility of the edge-bending center can adapt to the rapid changes in the market and personalized demand, helping enterprises to respond quickly to market changes and seize market opportunities.

As an efficient and highly accurate processing equipment, the edge bending center is playing an increasingly important role in the steel furniture industry. Through the introduction of advanced equipment and technology, such as edge bending centers, steel furniture enterprises can improve production efficiency, enhance product quality, reduce labor intensity, promote technological innovation, and adapt to market demand. In future development, with the continuous progress of technology and the expansion of application areas, the application of the edge bending center in the steel furniture industry will be more extensive and in-depth.

The edge bending center has been tested by a variety of customer groups, with high stability, high precision, high stability, widely recognized by the customer group, and the price of raw materials and the fluctuation of transportation costs will change. If you need to buy the edge bending center, please contact us for the latest quotation (sales@weiims.ntesmail.com).

Zhejiang Weiims Intelligent Equipment Co., LTD., supply edge bending center, Zhejiang Weiims Intelligent Equipment Co., LTD. Is committed to the research and development of sheet metal flexible manufacturing technology,edge bending center can greatly improve production efficiency, improve production capacity, reduce the workload of production workers. Improve the degree of enterprise automation production.