CNC sheet metal flexible punching and shearing line in the steel furniture industry applications

With the continuous development of science and technology, CNC sheet metal flexible punching and shearing lines are advanced metal processing equipment in metal product production and are increasingly widely used. The steel furniture industry is an important part of the production of metal products, and the demand for CNC sheet metal flexible punching and shearing lines is also growing. In this article, we will explain the application of CNC sheet metal flexible punching and shearing lines in the steel furniture industry, including its working principle, equipment features, application advantages, and practical application cases.

CNC sheet metal flexible punching and shearing line working principle and equipment features

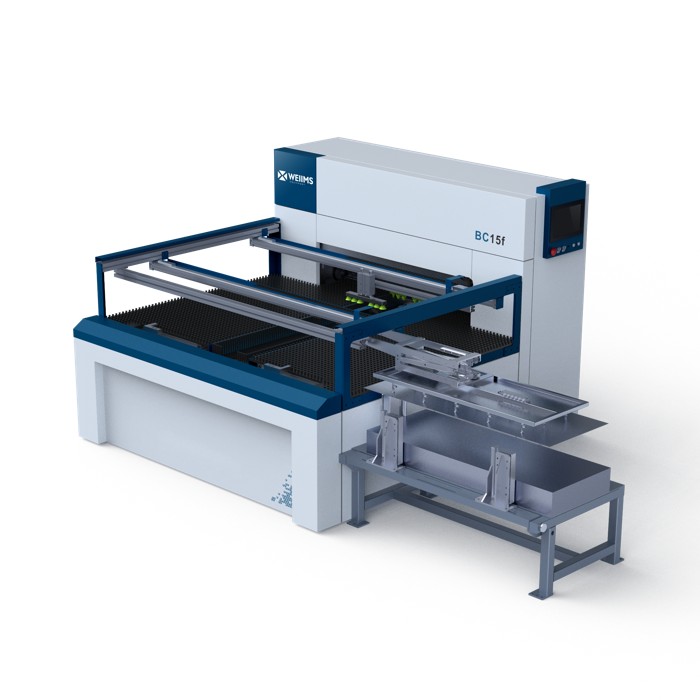

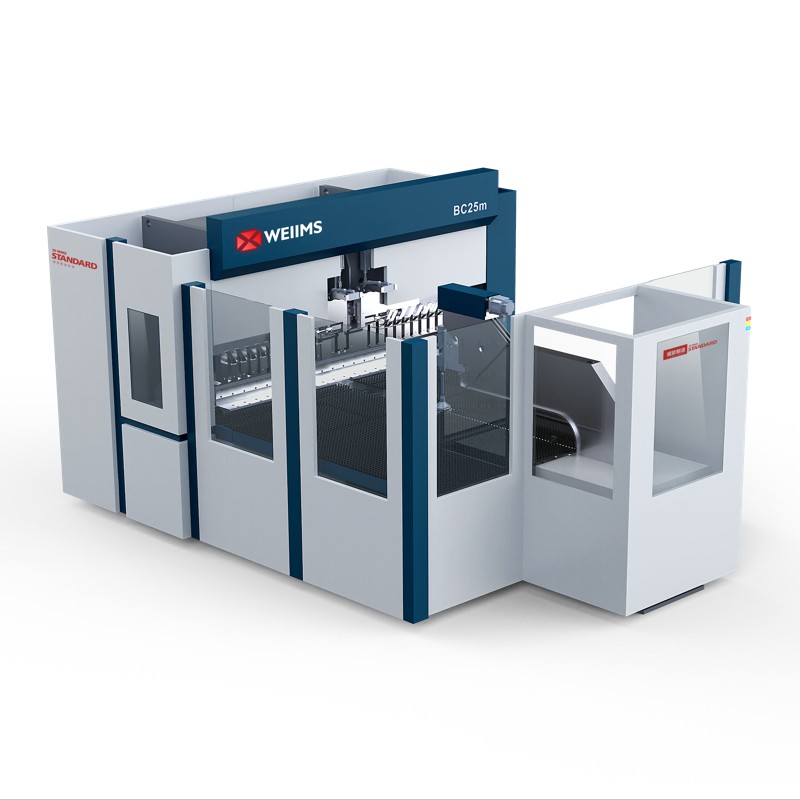

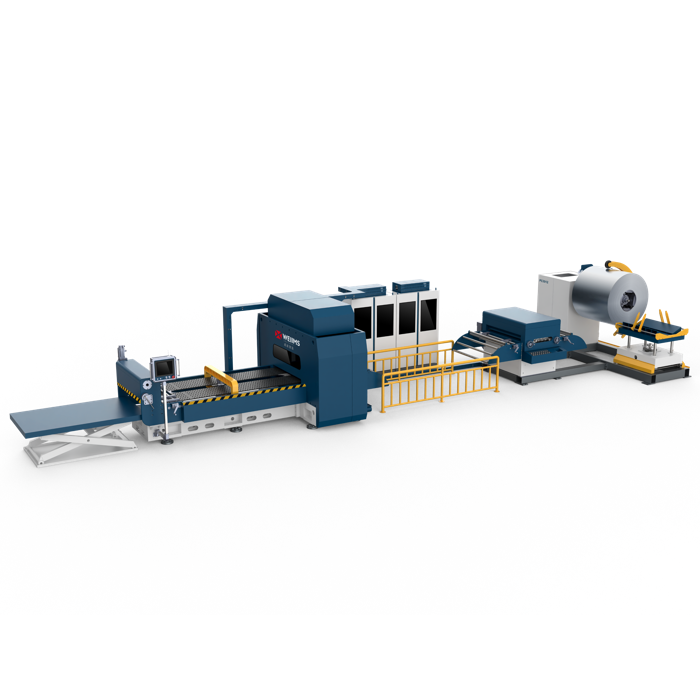

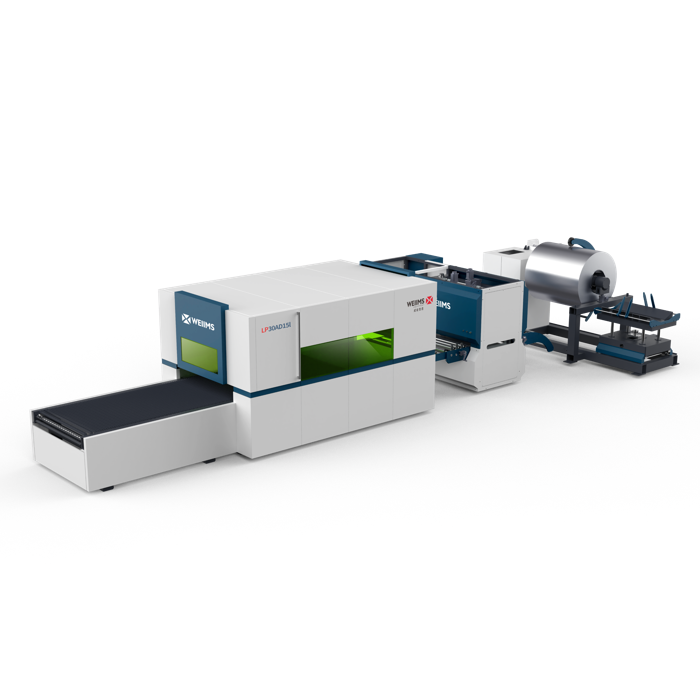

CNC sheet metal flexible punching and shearing line is a set of feeding, stamping, and shearing in one of the automated metal processing equipment. It carries out precise control of the stamping mold through CNC technology to realize precise sheet metal processing. Its main components include feeding, stamping, shearing, control, and so on.

Feeding system: It adopts a high-precision servo motor drive to ensure the stability of feeding precision and speed. At the same time, it can realize automatic feeding and sequencing of many different specifications of metal sheets to improve production efficiency.

Stamping system: adopting high-precision stamping molds, driven by servo motors, to realize accurate stamping and forming of metal sheets. Stamping molds can be customized according to actual demand to meet the needs of different shapes and sizes of metal product production.

Cutting system: High-precision cutting of metal sheets. The cutting section is smooth and burr-free, which can meet the requirements of the steel furniture industry for cutting precision.

Control system: adopts advanced numerical control technology to realize precise control of the whole production process. The control system can carry out real-time monitoring and adjustment of feeding, stamping and shearing to ensure the stability and efficiency of the production process.

In addition, the CNC sheet metal flexible punching and shearing line has the following features:

High precision: through precise control of CNC technology, it can realize high-precision production of metal products and improve product quality.

High efficiency: continuous automatic production can be realized, greatly improving production efficiency and shortening the production cycle.

Flexibility: It can be customized according to the actual demand to meet the demand for the production of metal products of different shapes and sizes. At the same time, it can realize automatic feeding and sequencing of many different sizes of metal sheets, improving production efficiency.

Easy to maintain: Adopting a modularized design makes it convenient to maintain and repair the equipment. At the same time, the control system can monitor and adjust the running status of the equipment in real-time to ensure its stability and reliability.

Advantages of CNC sheet metal flexible punching and shearing line in the steel furniture industry

Improve production efficiency: CNC sheet metal flexible punching and shearing lines can realize continuous automatic production, compared with traditional manual or semi-automatic production methods, which has significantly improved production efficiency.

Reduce costs: Through precise control of CNC technology, labor costs and material waste can be reduced, thus reducing production costs.

Improve product quality: CNC sheet metal flexible punching and shearing lines have high-precision processing capability, which can ensure the size and shape precision of metal products and improve product quality.

Increase market competitiveness: The introduction of CNC sheet metal flexible punching and shearing lines can enhance enterprises' production automation level and improve their competitiveness. At the same time, by providing high-quality products, it can increase the competitiveness of enterprises in the market.

Adapt to market demand: CNC sheet metal flexible punching and shearing line can be customized according to market demand to meet the production needs of metal products of different shapes and sizes. This can better adapt to market demand and increase the market share of the enterprise.

Reduce labor intensity: Traditional manual or semi-automatic production methods require workers to carry out tedious labor, while the introduction of CNC sheet metal flexible punching and shearing lines can greatly reduce the labor intensity of workers and improve production safety and work efficiency.

Improve the level of production management: CNC sheet metal flexible punching and shearing line control system can realize the precise control and management of the entire production process. Through real-time monitoring and analysis of production data, it can help enterprises optimize the production process and improve production efficiency and management levels.

Practical application cases

In order to improve production efficiency and product quality, the steel furniture manufacturer purchased a CNC sheet metal flexible punching and shearing line. The equipment adopts advanced punching and shearing technology, which can realize the production of high-precision metal products. In practice, the equipment has performed well, not only improving production efficiency but also reducing the scrap rate, bringing significant economic benefits to the enterprise. At the same time, the introduction of this equipment also improves the production automation level of the enterprise and enhances its competitiveness. Specifically, the enterprise, through the introduction of CNC sheet metal flexible punching and shearing line, achieved the following improvements:

Improvement of production efficiency: The equipment can realize continuous automated production and can realize unmanned production. Compared with the traditional manual or semi-automatic production methods, the production efficiency has increased by more than 50%.

Reduced costs: With precise CNC technology control, this equipment reduces labor costs and material waste, lowering production costs by about 20%.

Improve product quality: The equipment has high precision machining capability, which ensures the size and shape accuracy of metal products, reduces the defective rate, and improves product quality and customer satisfaction.

Increase market competitiveness: The introduction of this equipment enhances the production automation level of the enterprise and improves its competitiveness. At the same time, by providing high-quality products, the enterprise increased its market share and brand influence.

Achieve customized production: the equipment can be customized according to customer needs to meet the production needs of metal products of different shapes and sizes. This allows the company to better adapt to market demand and increase its market share.

Improve production safety: The introduction of this equipment reduces the labor intensity of workers, reduces the incidence of work-related accidents and improves production safety.

Optimize production management: The control system of this equipment can realize precise control and management of the whole production process. Through real-time monitoring and analysis of production data, the enterprise has optimized the production process and improved production efficiency and management levels.

As an advanced metal processing equipment, CNC sheet metal flexible punching and shearing line has a wide range of application prospects in the steel furniture industry. Its high efficiency, high precision, flexibility, environmental protection, and energy saving, as well as easy maintenance, make it a significant advantage in the steel furniture industry. Through the introduction of CNC sheet metal flexible punching and shearing lines, steel furniture manufacturers can improve production efficiency, reduce costs, and improve product quality, thereby enhancing the competitiveness of enterprises.

CNC sheet metal flexible cutting wire through a variety of customer groups tests, with high stability, high precision, high stability widely recognized by customer groups, by the impact of raw materials and transportation costs, the price will change, if you need to buy a CNC sheet metal flexible cutting wire, please contact us to get the latest quotation (sales@weiims.ntesmail.com).

Zhejiang Weiims Intelligent Equipment Co., LTD., supplies CNC sheet metal flexible cutting wire; Zhejiang Weiims Intelligent Equipment Co., Ltd. is committed to engaging in the research and development of sheet metal flexible manufacturing technology, CNC sheet metal flexible cutting wire can greatly improve production efficiency, improve production capacity, reduce the workload of production workers. Improve the degree of enterprise automation production.