Bending Centers VS Robotic Bending Cells

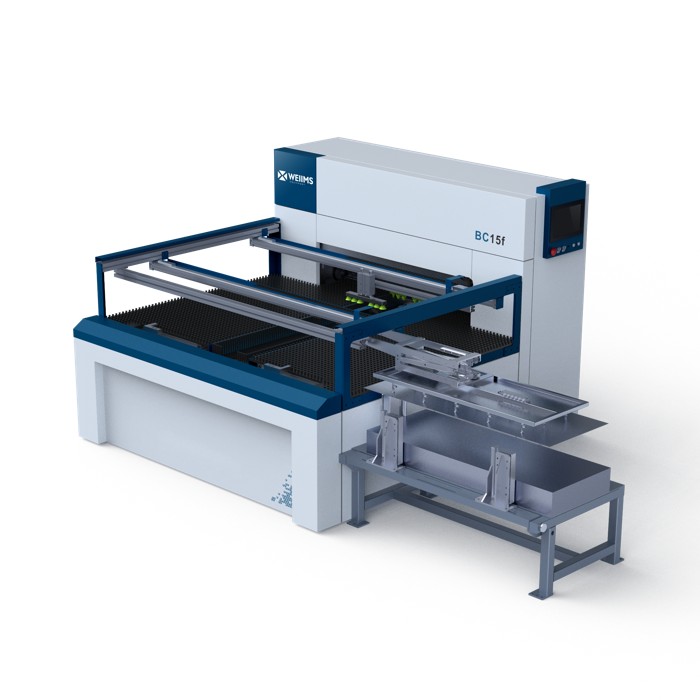

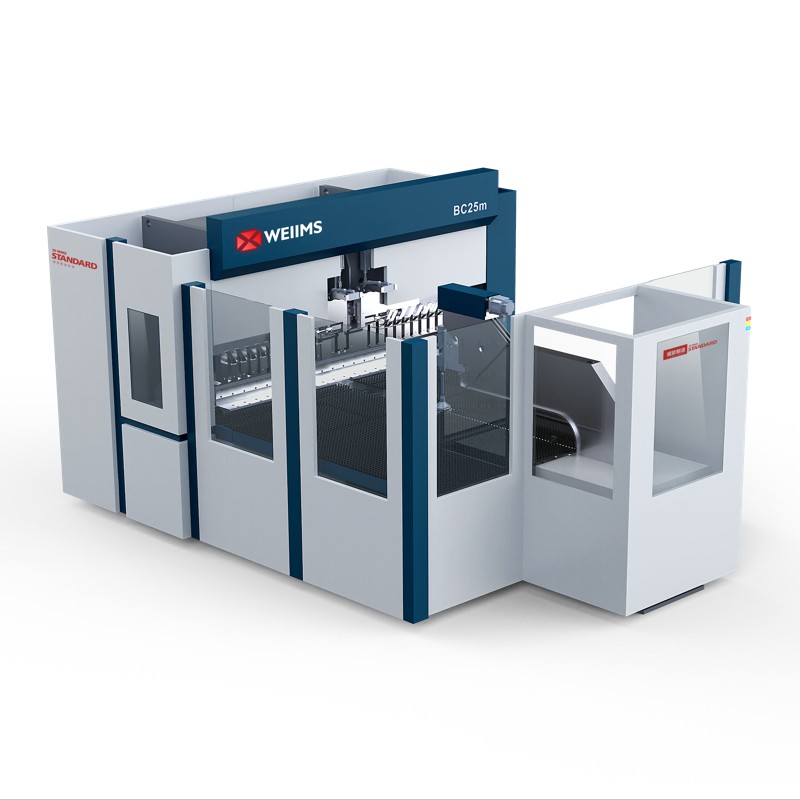

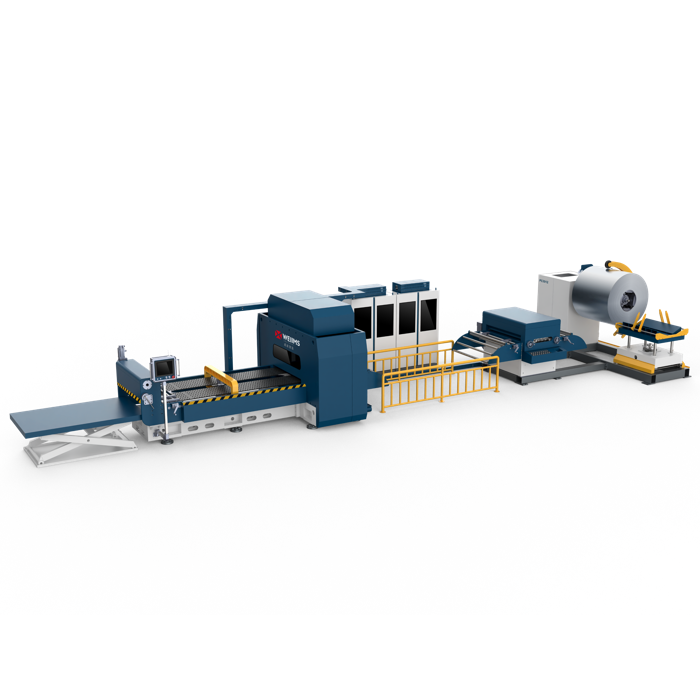

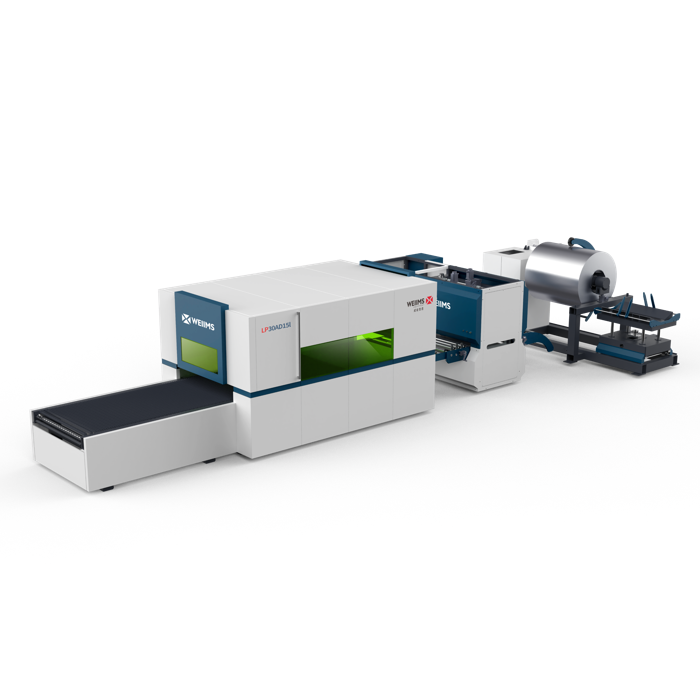

Bending centers and robotic bending cells are two different types of sheet metal bending equipment, and they have some significant differences in design and application. A bending center is an efficient, high-precision sheet metal bending machine that typically consists of multiple bending cells. This design allows the bending center to make multiple bends in sheet metal at the same time to create more complex shapes. Bending centers are typically used for large-scale, high-precision and complex shape bending of sheet metal.

Robotic bending cells are a more flexible type of sheet metal bending equipment, which usually consists of robotic arms that move through space with the workpiece to bend the sheet metal. This design allows for greater flexibility and programmability of the robotic bending cell, as the robot arm can easily change the bending path and angle. Robotic bending cells are typically used for small-scale, multi-species, and shape-variable bending of sheet metal.

Structure and design

A bending center is usually a large, stationary piece of equipment with a complex structure that requires precise control of the position and trajectory of each bending cell to ensure high-precision bending processing. The design of a bending center usually requires consideration of sheet metal transport, positioning, bending, and processing sequences to ensure that the entire process is smooth and efficient.

In contrast, a robotic bending cell is usually a smaller, movable device with a relatively simple structure that relies heavily on the robot's motion control to achieve sheet metal bending. The design of a robotic bending cell usually requires consideration of the robot's trajectory, the design of the bending mold, and the positioning of the sheet metal to ensure high-precision bending processing.

Processing Capability and Accuracy

The bending center usually has a large processing capacity and high accuracy due to its large structure and precise control mechanism. It can perform multiple bending of sheet metal to realize processing of complex shapes, and has a long service life and low maintenance costs. In addition, thanks to its high-precision control system, the bending center can also achieve high-precision bending processing to meet a variety of different processing needs.

Although the robot bending cell has a simple structure, its processing capability and accuracy may be affected by the robot because it depends on the robot's motion control. However, due to its programmability and flexibility, the robotic bending cell can be adapted to different processing needs in a short period of time and can realize the processing of complex shapes. In addition, the processing capability and accuracy of robotic bending cells are constantly improving due to the continuous development of robot technology.

Scope of application and productivity

Bending centers are suitable for large-scale, high-precision and complex shape bending of sheet metal, especially for scenarios that require mass production. Thanks to their large structure and efficient production capacity, bending centers can quickly and accurately complete the bending of large quantities of sheet metal, increasing productivity.

Robotic bending cells, on the other hand, are suitable for small-scale, multi-species and shape-variable sheet metal bending, especially for scenarios that require rapid line adjustments. Thanks to its programmability and flexibility, the robotic bending cell can be easily adapted to different processing requirements and can process complex shapes in a short time. In addition, the robotic bending cell can be used in conjunction with CNC machine tools and other automation equipment to achieve a high degree of automation and intelligence in the entire production line.

Cost and Maintenance

Bending centers, as a well-established type of sheet metal bending equipment, are usually expensive to purchase. However, due to its efficient processing capability and long service life, bending centers can provide a good return on investment in long-term production. In addition, the maintenance costs of bending centers are relatively low due to their consistent performance and low failure rate.

Robotic bending cells are usually less expensive to purchase but require specialized technicians for maintenance and commissioning due to their high technical content. In addition, the maintenance cost of robotic bending cells is also higher, as the robot's performance needs to be checked regularly and wearing parts need to be replaced. However, due to their programmability and flexibility, robotic bending cells can pay off well in short-term production.

Overall, bending centers and robotic bending cells each have their own advantages and disadvantages. Bending centers are suitable for large-scale, high-precision, and complex shape sheet metal bending, while robotic bending cells are suitable for small-scale, multi-variety, and variable shape sheet metal bending. When choosing which equipment to use, you need to consider the specific application scenarios and processing needs. If you need a large-scale, high-precision, and complex shape of the bending process, you can consider the use of bending centers; if you need a small-scale, multi-variety, and variable shape of the bending process, you can consider the use of a robotic bending cell.

Bending center through a variety of customer groups tests, with high stability, high precision, high stability widely recognized by customer groups, by the impact of raw materials and transportation costs, the price will change if you need to buy a Bending center, please get in touch with us to get the latest quotation (sales@weiims.ntesmail.com).

Zhejiang Weiims Intelligent Equipment Co., LTD. supplies a Bending center. Zhejiang Weiims Intelligent Equipment Co., Ltd. is committed to engaging in the research and development of sheet metal flexible manufacturing technology; multilateral bending centers can greatly improve production efficiency, improve production capacity, and reduce the workload of production workers. Improve the degree of enterprise automation production.